Butt Welding Process

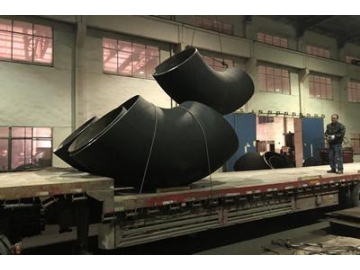

For production of large size seamed elbow pipe fittings, we usually place two steel plates into corresponding mold first, conduct compression forming with hydraulic machine and put these two pieces together through butt welding. One of the biggest advantage of the production process is that the caliber obtained is ranging from 6 to 100 inches and the largest wall thickness could be 100mm.

For miter elbow pipe fittings, where multiple pieces are welded together, the largest caliber we could provide is 160 inches. Or we could produce this kind of elbow according to customers’ design. During miter elbow production process, we will conduct compression forming directly if the raw steel plate is relatively thin. If the plate is thicker, heating will be required before forming. Once formed, the semi-finished pieces will be welded together by twos. Then X-ray films will be scanned on 100 percent of the butt weld to detect any possible defects. (In general, the X-ray films will be kept for 5 years or longer time if required.) If the welding is qualified, then heat treatment and surface treatment will be conducted subsequently.

Production Process- Steel plate feeding

- Cutting

- Press forming

- Welding

- Non-destructive testing

- Heat treatment

- Calibration

- Metal processing

- Surface treatment

- Inspection

- Identification

- Shipping

| Name | Qty. |

| 3000tons four-post hydraulic press | 1 |

| 1500tons four-post hydraulic press | 1 |

| 1000tons four-post hydraulic press | 1 |

| 630tons four-post hydraulic press | 1 |

| 500tons four-post hydraulic press | 2 |

| 315tons four-post hydraulic press | 5 |

Stainless Steel Pipe Fittings: ASTM A403 304/304L, 316/316L, 317/317L, 904/904L, 321/321H, 304H, 316H, 347/347H, etc.

Carbon Steel Pipe Fittings: ASTM A234 WPB, WPC, Q235B, 16Mn/ Q345B, etc.

Low Temperature Steel Pipe Fittings: ASTM A420 WPL3, WPL6, WPL8, WPL9, etc.

Alloy Steel Pipe Fittings: ASTM A234 WP11, WP22, WP5, WP9, WP91, etc.

Pipeline Steel Pipe Fittings: ASTM A860 (MSS SP-75) WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80, etc.

Duplex and Super Duplex Stainless Steel Pipe Fittings: ASTM A815 S31803, S32205, S32304, S32760, S32550, S32750, S33400, etc.

Nickel Alloy Pipe Fittings: ASTM B564 N10276, N04400,N06600,N06625, N06690,N08800,N08825,N08020,N08810, etc.

And titanium pipe elbow, copper pipe elbow and non-ferrous pipe elbow, etc.