Capabilities

Sunkey operates a food packaging area occupying 20,000 m2 and a 4,000 m2 Class D GMP clean room. We also operate a complete set of production and processing equipment, allowing us to complete the full bag production process in house, from raw material procurement, all the way to inspection.

We have 5 printing machines, as well as an advanced automatic ink color mixing machine, so that with the use on non-benzene printing inks, we are able to carry out 12 color printing at a maximum printing width of 1250mm. After printing, the product will be tested through a double detection process, including the automatic high speed precision inspection machine and quality inspection department. Only those products deemed qualified will leave the factory.

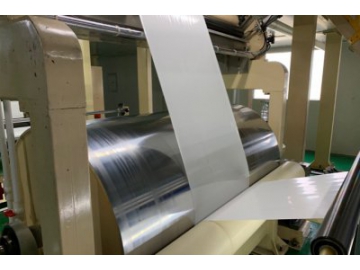

Our company is equipped with 2 dry laminating machines, 4 solvent-free laminating machines and 1 coating laminating machine with the coating width of 2,300mm to meet a variety of laminating requirements.

Our company has 8 high-speed slitting machines and 10 multifunctional bag making machines to ensure an on-time delivery, every time.

Our company is equipped with 3 200 m/min inspection machines to ensure all products are tested. We also have 10 high-speed digital ink-jet printers for variable data printing to ensure that every pouch has its own coding, ensuring product tracking and after-sales services are more convenient.

Sunkey has established a complete quality management system to ensure the quality and safety of raw materials are guaranteed from the source. The raw materials are mainly sourced from internationally known companies, including DuPont Teijin Films, POLOFILM(USA), Unitika, SHOWA Corporation and Sumitomo Group. We have a monthly assessment form, audit plan and audit report to every supplier. We also maintain samples of every raw material for a specific period.

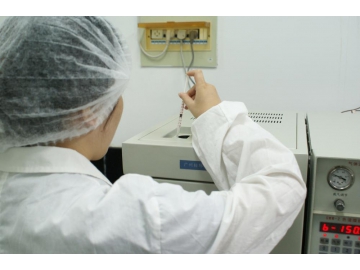

Moreover, we have built a Class 10,000 clean room for microbiological testing, equipped with complete testing equipment. We will carry out an extensive array of tests, including tests for WVTR, OTR, residual solvent, peel strength, tensile strength and elongation, sealing temperature, heat-sealing strength of finished products and more.