Croissant Lines

Croissant Machines

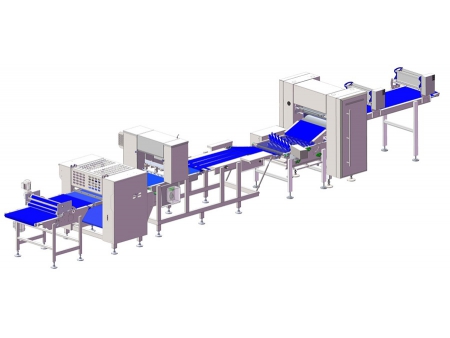

From the traditional straight and rolled croissant, to the filled croissant: the croissant product group is expanding continuously. Shenchen Machinery has over two decades of experience in producing production lines for croissants. The croissant machine features a modular design, allowing you to produce both filled and unfilled croissants with the same production line. Flexibility without compromising product quality and your return on investment.

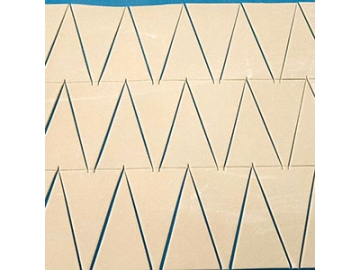

The croissant production line can produce croissants with or without fillings. With rolling cutter, dough sheet can be cut into different shapes (such as triangle, square, strip, round etc.) and 2, 3, or 4 rows of simultaneous croissant production is available.

Product display

- The croissant production line is a patented product of our company. With unique negative pressure curling unit (the negative pressure can make sure the fixed location of dough sheets and ensures the neat appearance of final products), the croissant line has better adaptability about dough shape, thickness and hardness.

- The curling process has little stretching effect on the dough sheets, which maintains the original internal structure of doughs and produces that are close to hand-made ones.

- The feeding machine connected to the feeding belt can be adjusted to different height, which makes it easier to clean the belt.

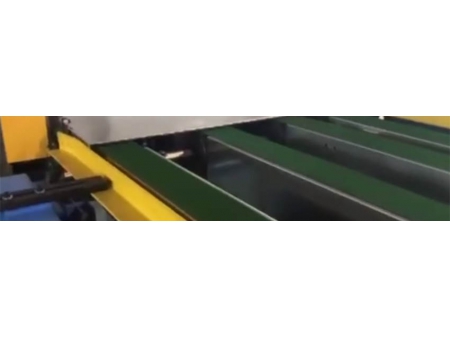

- There are patterned cutting roller and round cutter mounted on the equipment, both carry an anti-stick structure and are coated with Teflon. The cutting roller is driven by the belt underneath and is easy to adjust cutting force and replace cutters.

- The leftover material will be discharged from the outlet on both sides. Mention that sometimes soft and sticky materials would block the waste outlet and need to be cleaned manually.

- Various formulas can be set manually by the PLC screen, including rows division time, falling position, row spacing, running speed. The equipment will be already set correctly according to customer’s special needs, so costumers can use those parameters immediately.

- Dough calibrator (optional): After the laminating process, the calibrator stabilizes the dough at the desired speed, thus ensuring a constant production standard which fosters a better control of the production costs. With this unit, the reject rate can be greatly reduced and uniform weight of each croissant can be ensured.

Related products

Send Message

Most Recent

More

Other Products

Videos