Crushers

CITIC Heavy Industries (CITIC HIC) has been striving to technological innovation since 60 years ago. Our years of building up have led us to a respectable achievement in equipment performance, intelligent control, maintenance and spare parts supply services that have reached international advanced level within the mineral processing industry. Our crushers have been exported to a number of countries such as Sweden and Brazil, and widely used in coarse crushing operations of iron ores, copper ores, gold ores and molybdenum ores. Numerous projects that we have successfully executed are the evidence of our ability to provide safe, reliable, energy-saving and high-efficiency crushing equipment solutions.

- Design concept, closely adhering to the philosophy of environmental protection and energy saving

- A wealth of experience in designing and manufacturing of crushers

- Unique robust construction, ensuring high reliability and safe operation

- International manufacturing and inspection standards

- Intelligent control and remote monitoring

- Ergonomic design, easy to operate and maintain

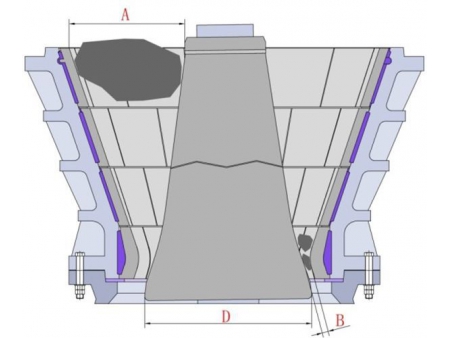

- Exclusive structure of crusher cavities with durable materials, extending the life cycle of crusher liner

- Entire process follow-up service

- Offering full range of spare parts, and optimization & upgrade service

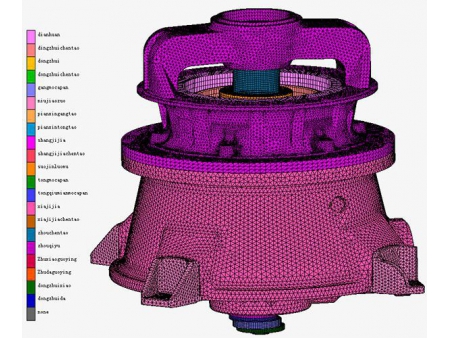

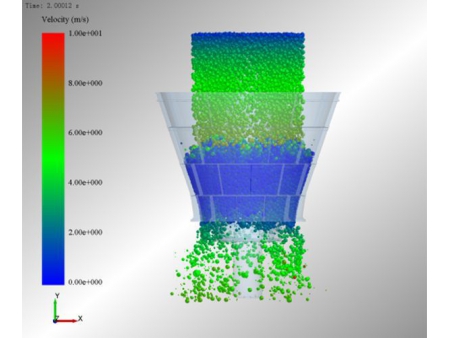

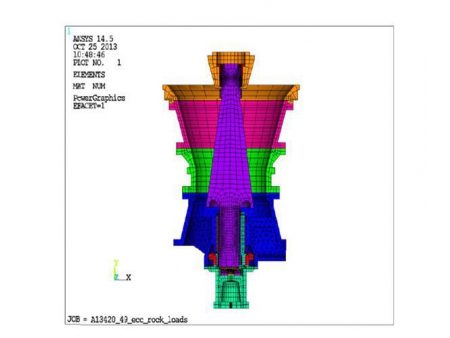

CITIC HIC engineers employ EDEM software to simulate a variety of different conditions, evaluate the crusher parameters, and perform finite element analysis of dynamic load, fatigue failure, lubrication, fluid flow and kinematics to design and manufacture the crushing equipment that best satisfies customers' requirements of ore characteristics, particle size distribution and productivity.

| Model | Feed opening | Max. feed size | Discharge opening | Crushing capacity | Mantle bottom diameter | Motor | Crusher weight | |

| Power | Rotation speed | |||||||

| mm | mm | mm | t/h | mm | kW (Max.) | r/min | t | |

PXZ 42-65 | 1100 | 900 | 140-175 | 1800-2850 | 1650 | 400 | 590 | 122 |

PXZ 50-65 | 1270 | 1050 | 150-175 | 2200-2950 | 1650 | 400 | 590 | 158 |

PXZ 54-75 | 1375 | 1180 | 150-200 | 2620-4000 | 1910 | 650 | 590 | 229 |

PXZ 62-75 | 1600 | 1400 | 150-200 | 2670-4325 | 2000 | 650 | 590 | 284 |

PXZ 60-89 | 1524 | 1300 | 160-230 | 4200-5810 | 2260 | 800 | 590 | 355 |

PXZ 60-113 | 1524 | 1300 | 160-260 | 5430-10000 | 2870 | 1200 | 590 | 552 |

New Type Gyratory Crusher, PXZ Ⅲ Series

| Model | Feed opening | Max. feed size | Discharge opening | Crushing capacity | Crusher weight |

| mm | mm | mm | t/h | t | |

PXZ 42-65Ⅲ | 1100 | 900 | 140-175 | 2300-5250 | 123 |

PXZ 50-65Ⅲ | 1270 | 1050 | 150-175 | 2400-6350 | 159 |

PXZ 54-75Ⅲ | 1375 | 1180 | 150-200 | 2900-7500 | 231 |

PXZ 63-79Ⅲ | 1600 | 1400 | 150-200 | 3000-8750 | 285 |

PXZ 60-89Ⅲ | 1524 | 1300 | 160-230 | 4500-12500 | 356 |

PXZ 70-89Ⅲ | 1778 | 1450 | 160-230 | 5000-15000 | 432 |

PXZ 60-113Ⅲ | 1524 | 1300 | 160-300 | 5600-17000 | 553 |

| Model | Feed opening | Max. feed size | CSS discharge opening | Crushing capacity | Speed of eccentric shaft | Motor power | Crusher weight |

| mm | mm | mm | t/h | r/min | kW | t | |

| PE510×800 | 510×800 | 400 | 50-175 | 70-350 | 350 | 75 | 11 |

PE580×930 | 580×930 | 500 | 60-175 | 120-420 | 330 | 90 | 13 |

PE760×1000 | 760×1000 | 600 | 70-200 | 150-500 | 260 | 110 | 24 |

PE850×1100 | 850×1100 | 700 | 70-200 | 180-600 | 230 | 160 | 30 |

PE950×1250 | 950×1250 | 800 | 100-250 | 280-810 | 220 | 160 | 45 |

PE1100×1200 | 1100×1200 | 900 | 125-275 | 330-850 | 220 | 185 | 51 |

PE1100×1400 | 1100×1400 | 900 | 125-275 | 380-1050 | 220 | 200 | 62 |

PE1200×1400 | 1200×1400 | 1000 | 125-250 | 360-900 | 220 | 200 | 58 |

PE1200×1600 | 1200×1600 | 1000 | 150-300 | 480-1100 | 220 | 250 | 93 |

PE1300×1700 | 1300×1700 | 1100 | 150-300 | 520-1250 | 220 | 300 | 83 |

PE1500×2000 | 1500×2000 | 1200 | 175-300 | 720-1500 | 200 | 400 | 154 |

| Model | Crushing capacity | Max. feed size | Hydraulic gyratory crusher | Feed opening width | Discharge opening width | Belt conveyor capacity | Slewing crane |

| t/h | mm | mm | mm | t/h | |||

PSZ 2000-B | 1500-2950 | 1000-1200 | PXZ 42-65 | 1070/1270 | 150-180 | >2000 | Main hook 60t |

| PXZ 50-65 | Auxiliary hook 20t | ||||||

PSZ 3000-B | 2200-3600 | 1100-1400 | PXZ 63-79 | 1600/1370 | 150-200 | >3000 | Main hook 70t |

| PXZ 54-75 | Auxiliary hook 20t | ||||||

PSZ 4000-B | 4200-5600 | 1200-1300 | PXZ 60-89 | 1500 | 160-230 | >4000 | Main hook 80t |

| Auxiliary hook 20t | |||||||

PSZ 8000-B | 5400-10000 | 1200-1400 | PXZ 60-113 | 1500 | 175-260 | >8000 | Main hook 125t |

| Auxiliary hook 20t |

| Model | Feed opening | Max. feed size | Discharge opening | Crushing capacity | Speed of eccentric sleeve | Main shaft adjustment | Motor power | Max. lift during maintenance | Crusher weight |

| mm | mm | mm | t/h | r/min | kW | t | t | ||

CCS420C | 250-320 | 200-250 | 20-50 | 80-230 | 200-250 | Hydraulic adjustment | 90 | 2.5 | 7.1 |

CCS430C | 300-400 | 250-350 | 20-50 | 100-350 | 200-250 | 150 | 5.2 | 12.3 | |

CCS440C | 400-550 | 300-450 | 25-55 | 200-500 | 200-250 | 220 | 8.5 | 20 | |

CCS660C | 570-700 | 450-600 | 35-75 | 300-1000 | 200-250 | 315 | 16 | 36 | |

CCS420 | 50-180 | 30-150 | 5-30 | 40-120 | 230-280 | 90 | 1.5 | 5.5 | |

CCS430 | 60-220 | 40-180 | 8-35 | 80-220 | 230-280 | 150 | 3 | 9.5 | |

CCS440 | 85-250 | 65-200 | 8-40 | 100-400 | 230-280 | 220 | 5 | 14.5 | |

CCS660 | 90-350 | 70-280 | 10-50 | 150-700 | 230-280 | 315 | 8 | 24.5 | |

CCS870 | 100-380 | 80-300 | 10-70 | 200-1500 | 230-280 | 520 | 13 | 51 | |

CCS880 | 120-420 | 100-360 | 15-75 | 350-2000 | 230-280 | 600 | 23 | 71.5 | |

CCS890 | 150-450 | 120-380 | 16-75 | 350-2600 | 230-280 | 750 | 25 | 79 |

| Model | Weight (kg) | Speed of transmission shaft | Power | Remark | ||||

| Total weight | Max. lift during installation | Max. lift during maintenance | Fixed cone assembly | Moving cone assembly | ||||

| (r/min) | (kW) | |||||||

CC200 | 11000 | 3850 | 2900 | 2900 | 1500 | 750-1200 | 132 | Light duty |

CC300 | 16500 | 5770 | 4100 | 4100 | 2200 | 700-1200 | 200 | Light duty |

CC400 | 24500 | 8570 | 5500 | 5500 | 3500 | 700-1000 | 315 | Light duty |

CC500 | 35000 | 12300 | 8360 | 8360 | 6100 | 700-1000 | 355 | Light duty |

CC800 | 72000 | 26500 | 21000 | 21000 | 11500 | 700-1000 | 630 | Light duty |

CC500M | 48000 | 17900 | 16300 | 16300 | 6400 | 700-1000 | 450 | Heavy duty |

CC800M | 122500 | 45500 | 27000 | 27000 | 16500 | 700-1000 | 630 | Heavy duty |

CC1000M | 155000 | 58500 | 33800 | 33800 | 18000 | 700-1000 | 800 | Heavy duty |

Swedish Mining Company LKAB

Semi-mobile gyratory crushing plant trial run (PSZ3000)

Swedish Mining Company LKAB

Semi-mobile gyratory crushing plant (PSZ3000)

Brazilian Miner Vale SA

Hydraulic gyratory crusher (PXZ-1500Ⅱ)

- High cost-effectiveness

CITIC HIC's crushers have the capacities and performance rivaling that of world's renowned brands, successfully entered European and American markets - Low failure rate

Reliable quality and performance - Low cost

High operating rate, easy maintenance, less labor cost - Excellent service

On-site installation guide, start-up and running support, equipment acceptance (mechanical, hydraulic and electrical systems), remote monitoring & fault diagnosis, troubleshoot and maintenance, high quality original spare parts supply

-

Manufacturing

ManufacturingCasting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. -

Service

ServiceLifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.