Custom Sheet Metal Fabrication Service

providing sheet metal parts, enclousure, and assembled product according to your requirement

As a professional sheet metal fabricator, we employ a talented team that is familiar with high-quality industry techniques and market trends. We utilize a complete set of processing equipment and quality control procedures to provide customers with excellent services. We provide accurate feedback to our customers in real time to ensure all operations are carried out according to their demands.

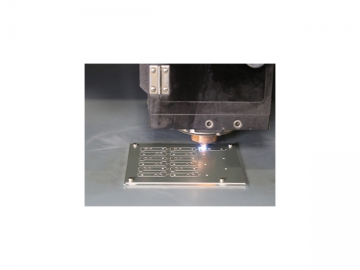

- We use reliable and highly efficient equipment to process customized sheet metal parts.

- Japan Amada CNC stamping

- Japan Amada/Toyo bending machine

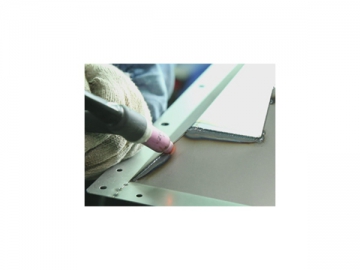

- Robotic arm welding

- MIG welding (CO2 gas)

- TIG welding

- Resistance welding

- Multi axis tapping machine

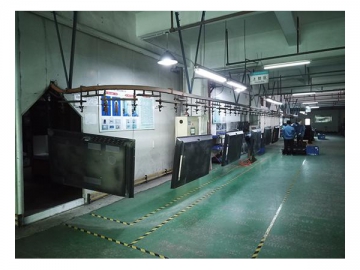

- Coating

- Assembly

In addition to the processing capacity of the equipment above, Jiatong can also provide additional services such as anodizing, electroplating and silk screening.

Jiatong employs a highly effective quality control group, ensuring the perfect flow of quality inspection independent from our mature processing system. The quality group is responsible for us passing ISO9001-2008 system certification in 2012. We have implemented advanced sheet metal inspection equipment, such as inspection instruments from InspecVision, chromatic aberration gauge, coating thickness gauge, etc.

Our entire team of core technicians have many years of experience in large-scale fabrication operations in American and Japanese factories. We have outstanding professional skills, flexibility, and management capacity. We are familiar with the ins and outs of many different features of products and their processing requirements.

1) SPCC (generally used in cold rolling carbon steel and steel belt)

2) SECC (electrolytic lead galvanized steel sheet): rust and corrosion resistant

3) aluminum plate: light weight and good rigidity

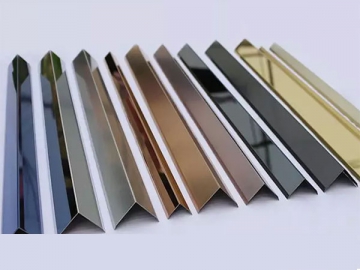

4) stainless steel: smooth surface, high rigidity and corrosion resistant

Considering the importance of transportation and delivery, EPE will be carefully filled around the sheet metals because EPE has good vibration absorption effect. In addition, we will customize wooden boxes instead of cartons, because the carton is not suitable for long-distance transportation and cannot protect the products well.