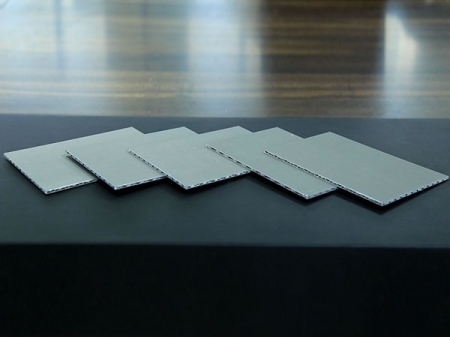

Zinc Primer

Introduction of Inorganic Zinc Primer:

Inorganic Zinc Primer made of two different types (A, B).The product made from ethyl silicate, zinc powder, filling, additive and solvent. The product has excellent anticorrosion properties, as well as water resistant, oil resistant, especially for cathode protecting.

Application of Inorganic Zinc Primer:

Inorganic Zinc Primer is applied for general anti-rust lacquer use.

Specifications:

Color: Iron Oxide RedH-31(primer), WhiteH55-32 (coating)

Specific Gravity: 1.60

Dosage: 0.35kg/m2

The Thickness: 180um (wet)

The Thickness: 60um (dry)

Ratio: 1:1 (A:B)

Application Time: 8hours, 25degree

Application Methods: bush, roll, spray

Solvent: Special, 5%-20%

Surface Dry: 30minutes, 25degree

Hard Dry: 24hours, 25degree

Solidify: 7days

The Interval between two washing:

More than 24 hours (shortest time), 25degree

Surface Finish: The surface of steel should meet the Swedish Sa2.5 standard or Sa3 standard.

Duration period: 6months

Flash Point: 13degree (A), 27degree (B)