Anticorrosion Paint

Introduction of Anticorrosion Paint:

Anticorrosion paint is made of two different parts (A, B). A is made from epoxy resin, Iron Oxide Red, dye, filling, etc; B is hardener. The product has excellent anticorrosion properties, as well as water resistant, oil resistant and chemical resistant and non-toxic.

Application of Anticorrosion Paint:

It is use as an anticorrosion paint for drinking vessel, it can also be use to tank others.

Specifications:

Color: iron oxide redH-31(primer), whiteH55-32 (coating)

Specific Gravity: 1.32(primer), 1.28(coating)

Dosage: 0.3kg/m2 (primer), 0.35kg/m2 (coating)

The Thickness: 180um (wet, primer), 190um (wet, coating)

The Thickness: 100um (dry)

Ratio: 100:30 (A:B, primer), 100:40(A:B, coating)

Application Time: 8hours, 25degree

Application Methods: bush, roll, spray

Solvent: Special, <5%

Surface Dry: 4hours, 25degree

Hard Dry: 24hours, 25degree

Solidify: 7days

The Interval between two washing:

24 hours (shortest time), 25degree

7days (longest time), 25degree

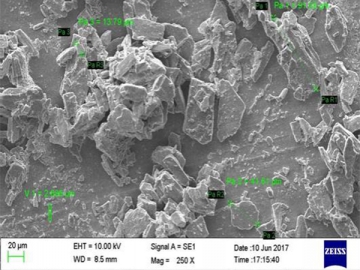

Surface Finish: The surface of steel should meet the Swedish Sa2.5 standard

Duration period: 12 months

Flash Point: 35degree