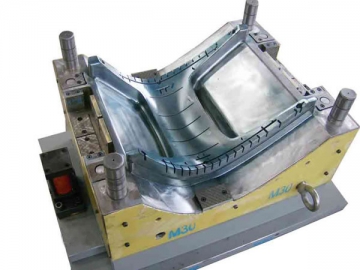

Mold Construction

Here at Haiyee, we invest heavily in good equipment, processes and talent. This gives us control over our mold tooling quality and services. It is our mission to not only meet customer expectations, but in many cases exceed them.

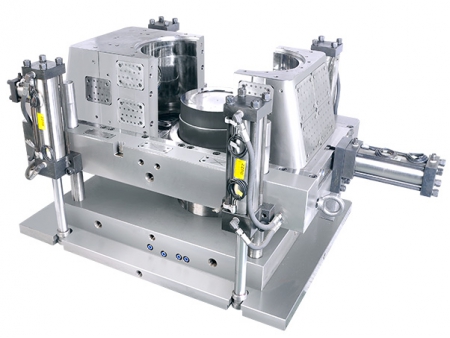

CNC Machine

Pictured above is our CNC machining center. This computer-controlled unit connects via internet to our programmer's computer. The programmer writes instructions for the CNC machine to follow, thereby maintaining overall control of the machining process. A high level of accuracy and flexibility can be achieved for each operation, be it rough or finish machining of molds in a broad range of sizes, cores and cavity shapes.

High-speed CNC milling machines

CNC milling machine

CNC precision machine

Max work area: 2000mm×1500mm

2-axis electrical discharge machining

Gun drilling machine

Wire EDM

Max work area: 1000mm×900mm

Machining, Assembly

Surface grinder machine

Radial drill

TIG welding Machine

Die spotting machine

Hydraulic Press 1500T

Press tonnage: 315T, 800T, 1500T

Mould heating manner: oil/electric/steam

Hydraulic cylinder brand: HPS, Parker, etc.

Flow control valve brand: Delta

Each press comes fitted with an oil heater to heat the mold during compression molding. The hydraulic press is bought with the purpose of trying out molds and batch production of molded parts. As molding technology and equipment continues to develop, we will update our processes and machinery to continue to improve our mold quality.

Injection Molding Machine 250T

86T, 180T, 250T, 800T

Available in different tonnages, the injection molding machine can meet customer needs for mold trial and batch production of injection molded parts.