Extrusion Pipe Capabilities

Thanks to our all-encompassing extrusion capabilities, we are able to provide customers with almost all types of pipes and pipe fittings.

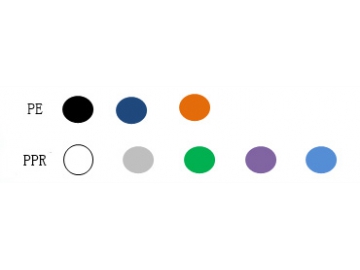

As a professional manufacturer of pipes and pipe fittings, our advanced production facilities are equipped with 14 PE extrusion lines, 3 PP-R pipe production lines and 1 aluminum plastic composite pipe production line. Our factory is also outfitted with 10 injection molding machines and large-scale forging equipment. All of these components play a huge part in the successful production of our high-quality pipes that will be made to meet the requirements of various specifications and die sinking. We have realized fully automated production achieving greater efficiency and our yearly output has surpassed 50,000 tons of pipes and 30,000 tons of brass fittings.

We only use 100% fresh PP-R and PE materials. No recycled or waste materials used guaranteed.

- PPR cold water pipes: 8001

- PPR hot water pipes: HYOSUNG R200P

- PPR pipe fittings: 8001

- PE water pipes: YGH041, 100S, TR480

- PE gas pipes: Imported raw material

- PE100: Basel CRP100BLACK, SABIC P6006, Borealis HE3490-LS

- PE80: Borealis HE3440-HD

PPR straight pipes: Available length of 4m

Diameter of pipe caliber (Outside diameter): 20mm-160mm

Available pipe diameter: 20mm 25mm 32mm 40mm 50mm 63mm 75mm 90mm 110mm 160mm

HDPE pipes: Available length of 6m or 12m

Diameter of pipe caliber: 20mm-1200mm, coil pipes from 20-63mm and straight pipes above 63mm

SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33--HDPE

S5, S4, S3.2, S2.5--PPR

Extrusion Workshop

Extrusion WorkshopZhejiang Jinyu Fengye Pipe Industry Co., Ltd. has more than 10 years of experience in PE and PPR pipe manufacturing. Our highly advanced extrusion workshop is equipped with over 10 pipe extrusion lines to manufacture pipes with various diameters from 20mm up to 1200mm.

2Battenfeld-Cincinati Extruder and 1 KraussMaffei Extruder from Germany

2Battenfeld-Cincinati Extruder and 1 KraussMaffei Extruder from GermanyThese three extruders imported from Germany enable higher production efficiency as well as higher product quality through stable performance, better smoothness and less tolerance.

Samples of Extruded Pipes

Samples of Extruded Pipes  Samples of Extruded Pipes

Samples of Extruded Pipes  Samples of Extruded Pipes

Samples of Extruded Pipes

Our product quality is maintained through strict processing requirements and thorough inspections throughout production. We are confident in our abilities through all steps from raw material purchasing, equipment processing, management, and inspection. All of these stages are conducted under specific standards to ensure the highest level of quality for each product.

Differential Scanning Calorimeter (DSC)

Differential Scanning Calorimeter (DSC)  Electronic Balance

Electronic Balance  Electronic Universal Testing Machine

Electronic Universal Testing Machine  Hydrostatic Tester

Hydrostatic Tester  Hydrostatic Tester

Hydrostatic Tester