Flexographic Printing Blades

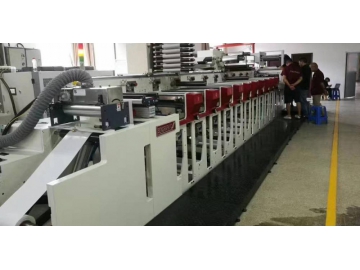

Flexographic printing is widely used for printing on packaging materials. It is a printing method which transfers ink to the substrate by anilox roller.

In flexographic printing, the doctor blade is used to remove excess ink from the anilox roller, so the pressure coming from the doctor blade should be low to reduce the wear on the anilox roller and improve the lifespan of the roller.

Flexographic printing usually uses water based ink, alcohol based ink and UV ink. So flexographic printing blades needs to have good durability and corrosion resistance. We recommend the following doctor blades which can meet the requirements of flexographic printing blades and are suitable for abrasive anilox rollers and the types of ink listed above.

Features

- Maximum speed is 500m/min。

- The pressure of anilox roller coming from doctor blade is low, which can improve the lifespan of the anilox roller.

Features

- Maximum speed is 400m/min。

- Good durability and corrosion resistance of doctor blade can reduce the wear of air cylinder.

Features

- Maximum speed is 400m/min。

- The doctor blade can reduce the wear of the anilox roller resulting from the blade.

- High quality coating ensures the doctor blades have good corrosion resistance.

Features

- Maximum speed is 250m/min。

- The stainless steel make sure the good corrosion resistance of doctor blade.

- The doctor blade can maintain good effects in removing excess ink even if the printing press is operating at a high speed.

Features

- Maximum speed is 250m/min。

- The doctor blade is suitable for water based ink, alcohol based ink and UV ink.

- Compared with common doctor blades, coating dotor blades have a longer lifespan.

Related products

Send Message

Most Recent

More

Other Products

Videos