How can ground anchor be available in 100% recovery?

1. Solutions for 100% recovery of ground anchor

(1)The company shall be responsible for choosing high-recovery products.

(2)Product production must stop when we found that they were not available for recovered, and performing remedy measure of casing drilling.

(3)The following documents should be submitted while having project acceptance of ground anchor:

a. Factory certificate in raw material, report on sample inspection of raw material, report on sample inspection of anchor recovery device.

b. Project construction record of anchor, anchor recovery record.

c. Test report on the carrying capacity of anchor.

d. Record for inspection and acceptance of concealed works.

e. Design change report.

f. Report on acceptance and evaluation of 100% anchor recovery.

g. As-built drawings (Planar, cutaway drawing of unrecovered anchors).

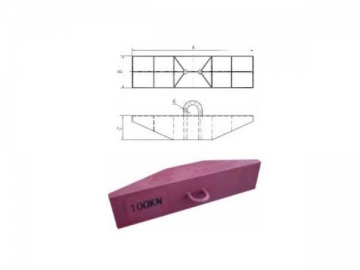

2. Technical solutions of hot melt removable anchor

(1) Product selection:

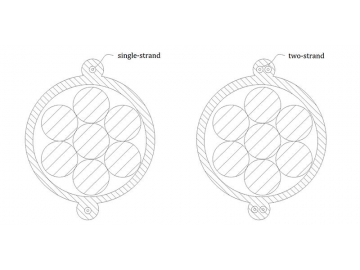

Two types optional: Single-strand and two-strand hot melt removable anchor.

(2) Construction control

a. Perform test on the hot melt removable before lowering the anchor and only when it is tested qualified, construction can start;

b. Conduct inspection after the construction to ensure that the anchor are available in normal electrical conduction, otherwise, the anchor should be taken out and re-construction should be made before the setting of cement;

c. Inspect the anchor for electrical conductivity before locking the anchor, if there is no electricity, appropriate remedy measures can be taken: The first one, taking out the anchor by drilling before no construction has been made on the main structure of the construction project; the other one is taking out the anchor by drilling after construction work has been made to the main structure of the construction, with the empty holes left after drilling filled with foam concrete.