Heat Shrinkable Tubing Workshop

The heat shrinkable tubing workshop is outfitted with an extensive line of equipment that allows for a monthly output of 6 million meters. Main processes carried out here include dosing, extruding, irradiation, expanding and packaging.

Extrusion workshop

- Our extrusion workshop is extremely large, and it is here where extruding and printing for heat shrinkable tubing is carried out.

- Hopper and feed opening

- The control panel controls each step of producing heat shrinkable tubing.

- Because the temperature of the screw is so high, it is equipped with fans to lower the temperature and prevent overheating.

- Extruder

- The cooling sink is 8 meters long. The temperature of the heat shrinkable tubing is very high after extruding, so the cooling sink is used to lower the temperature and further form the tubing.

- Traction machine

- The tensioner is used for enhancing the tension of heat shrinkable tubing.

The winding machine is used in the last step of the extrusion process for heat shrinkable tubing. It is used to wind the shrinkable tubing and rolling it into a bundle before the tubing is sent onto the next process.

The winding machine is used in the last step of the extrusion process for heat shrinkable tubing. It is used to wind the shrinkable tubing and rolling it into a bundle before the tubing is sent onto the next process. Irradiation Workshop

The irradiation workshop is also large enough to quickly manufacture the heat shrinkable tubing, and with two irradiation accelerators, the lead time is short.

The irraditation process is used for irradiating the heat shrinkable tubing by changing the molecular structure of the raw materials, allowing the shrinkable tubing to be easily formed after it is expanded.

- The tensioner is used for adjusting the speed of heat shrinkable tubing when it enters the irradiation room.

- Here, an employee is overseeing the heat shrinkable tubing in the irradiation room, and recording it.

Expanding Workshop

- The expanding workshop is expansive, and equipped with 3 types of expanding equipment: dry expanding equipment, large glycerol expanding equipment and small glycerol equipment.

- The large expanding equipment can process 9 heat shrinkable sleeves at the same time, and sends them to the glycerol heating process.

- The mold is used to expand the heat shrinkable tubing.

- These 9 heat shrinkable tubing are forming in the cooling sink.

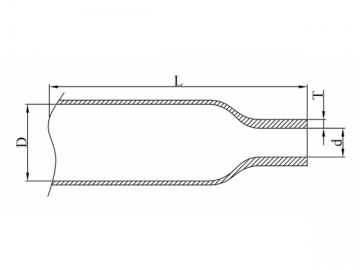

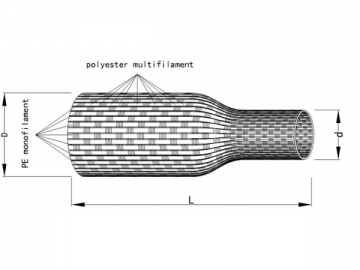

- This picture shows the heat shrinkable tubing after it is formed. It will be put into containers after going through the traction and ending machines. The diameter of the shrinkable tubing after it has expanded is 0.6-120mm.

- Expanding equipment

Related products

Send Message

Most Recent

More

Other Products

Videos