In-Mold Decoration and Water Transfer Printing Process

We specialize in custom water transfer mobile phone cases and IMD (in-mold decoration) designs. Each product also undergoes a high quality surface treatment for durability and feel. In addition to mobile phone cases, we also supply covers for tables, laptops, and many other electronic devices. The available surface treatments include gold blocking, rubber oil painting, and UV oil painting. Each provides a beautiful look to the cover. Customers need only provide us with their design patterns and we can complete the custom processing, packaging, and documentation for your casing products.

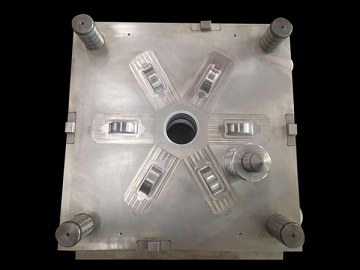

IMD means that the design is created within the injection molding die. We have a complete IMD line and outstaning team to create customized IMD handset shells for customers. We have designed one hundred sets of modules to produce mobile phone cases for models such as the iPhone 5, iPhone6, iPhone6s, iPhone6plus, iPhone7, iPhone7plus, Samsung S7, SamsungS7 edge, SamsungS8, and SamsungS8 edge. The materials of these cases can be acrylic, ABS, PC, PE, etc.

After providing us with the initial pattern, we will provide you with high quality IMD mobile phone cases.

- Print pattern

Positional punch

Positional punch  Stamping

Stamping  In-mold injection

In-mold injection  Finished product testing

Finished product testing

IMD shells are abrasion resistant and can protect the shell surface from scratching. Thanks to the hardened transparent thin film on the shell surface, the pattern ink is protected and can keep the color bright. It is also anti dust, moisture-proof and anti-deformation. We make sure the product is environmental friendly that it contains no solvent adhesives.

IMD mobile phone shell features

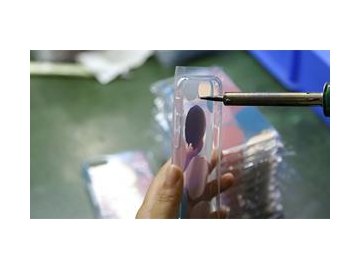

IMD mobile phone shell featuresWater transfer printing is a processing method that transfers a pattern to the surface of a plastic product by using a plastic film suspended in water. The image or pattern can be directly applied to the surface of the case by dipping it into the suspension.

Water transfer printing process: Print pattern

Print pattern  Positioning

Positioning  Cutting hole

Cutting hole  Trimming

Trimming  Dehydrating

Dehydrating  Base oil spraying: To enhanced patterns' adhesion

Base oil spraying: To enhanced patterns' adhesion  Spray rubber oil or UV oil

Spray rubber oil or UV oil  Oil drying

Oil drying  Quality testing

Quality testing

Water transfer printing is one of the most popular methods for the production of mobile phone shells. The rubber plastic products by water transfer printing can be either matte or highlighted which is decided by the oil type chosen. Water transfer printing can be applied to all kinds of plastic products, mainly for mobile phone shells, panel computer shells, portable source shells, mouses, etc.

Plastic products which have undergone water transfer printing have a nice gloss and feel great.

What's more, we can make the surface treatment more perfect by the processes of silk-screen, transfer printing, gold-blocking, or silver- blocking.