Laser Cutting / Engraving Leather

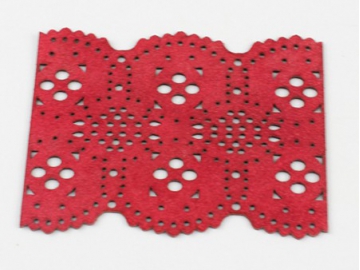

Traditional technology for leather processing is slow, high cost, and need complex plate making. Laser technology overcomes all these disadvantages. For example, laser cutting machine can cut various complex patterns quickly without the warping of the leather materials. It can perfectly reserve the natural texture and tactile effects of the leather materials, so laser cutting machine is widely used to process various leather products such as wallet, luggage, shoes, clothing, etc.

We proudly recommend our laser machines to you due to their perfect processing quality. They can help you to meet various consumer demands.

Advantages of laser process leather- Non-contact processing without material warping and fraying, the cutting edge is smooth, no post-processing is required

- Using computer program to control the processing, result strictly according to the drawings your input, deviation is within 0.1mm, very accurate

- Integrate cutting and engraving function into one machine, saving processing time and your investment

- Exhaust system removes dust and gas created during laser processing, keep the machine safe and clean

Image Gallery

Related products

Send Message

Most Recent

More

Other Products

Videos