CYL Vertical Type Laying Up And Steel Wire Armoring Machine

Application

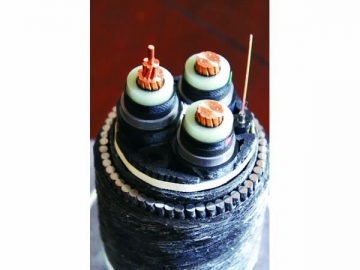

The vertical cable laying up machine is used for laying up MV, HV or EHV submarine cables, umbilical cables, and submarine photoelectric composite cables. Also, it is suitable for steel wire armoring.

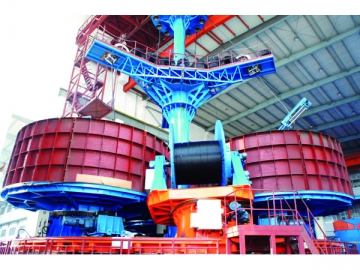

Features

1. Wire releasing units of the vertical cable laying up machine can be freely combined for making the cables of different cores.

2. This armoring machine has a bobbin loader on which a fiber unit can be laid. Therefore, it is applicable for cabling submarine photoelectric composite cables.

3. Because the main rotary table is supported by a large slewing bearing, the whole cable machinery is stable and reliable.

4. The tapered riding wheel will not slide on the track.

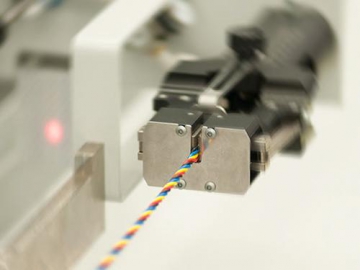

5. Our machine applies driven type pay off method. The constant tension is PID adjusted.

6. It applies a special traction mode to prevent the cable deformation and save electricity.

7. Each part of the vertical cable laying up machine is driven by individual motor. It is convenient to install and maintain.

Competitive Advantages

1. The vertical cable stranding part of this machine has the bobbin loader with a rotary table. It can release the wire without back-twisting, so as to make umbilical cables.

2. Our equipment can make long cables with large cross section.

3. Its large rotary table has high rotation speed. The cabling efficiency is extremely high.

4. The cabling machine comes with high degree of automation.

Improvement

1. Every independent wire coil unit is aslant placed for smooth wire feeding.

2. The vertical cable laying up machine applies a wire pay-off turntable that can realize the back twist paying-off.

3. The small turntable is supported by the slewing bearing rather than the under roller.

4. Diameter of the large turntable is increased to 20 meters.

Sales Performance

We have sold out 8 sets of vertical cable laying up equipment, 1 of which were exported to England.

| Configuration of drums (Turntable) | Max. rotation speed (rpm) | Cable core O.D. (mm) | Max. load capacity (kg) |

| 3*Ø7000/3*Ø 2000 | 3 | 25-114 | 200,000 |

| 3*Ø8000/3*Ø3150 | 3 | 25-114 | 300,000 |

| 3*Ø10000/3*Ø3150 | 3 | 25-114 | 450,000 |

| 9*Ø3150/3*Ø3150 | 5 | 10-60 | 20,000 |

| Configuration of armoring cage | Max. rotation speed (rpm) | Round steel wire | Flat steel wire |

| Ø630/60 Ø630/70 | 15 | Φ5.0, Φ6.0 | 7.5×2.5, 8.5×3.5 |

| Ø630/70 Ø630/80 | 15 | Φ5.0, Φ6.0 | 7.5×2.5, 8.5×3.5 |