Vacuum Casting Service

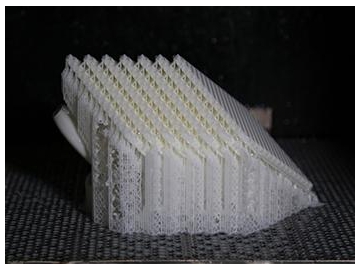

Vacuum casting is used to produce silicone molds from the original sample under a vacuum state and uses PU material to perform deaeration, stirring, pre-heating, injection molding and other processes. Secondary curing is carried out at 60℃ to 80℃ at a constant temperature to create a clone which is the same as its original model. This technology is suitable for small series production of prototypes with more complex structures, uniform wall thickness and the ability to carry out certain functions. We have 4 large-scale vacuum casting machines and 6 professional technicians to provide our customer with fast service and high-quality products.

- Vacuum casting provides high speed production and cheaper costs which lower the development costs, time taken and risk.

- Require rubberized application, parts with few materials shaped from wrapping.

- It is a good approach to conduct testing after small batch production on pre-launched products. As such, vacuum casting is suitable for small series production.

Suitable object

Small series test production samples with more complex structures, uniform wall thickness and the ability to carry out certain functions.

Suitable mold

Silicone mold (Lifespan 10-15pcs)

Injection molding materials

Polyurethane (PU), Polyoxymethylene (POM), ABS, Polypropylene (PP), Polycarbonate (PC)

Physical properties

ABS type, PP type, PMMA type, PC type, soft rubber

Cloning accuracy

±0.15mm/100mm

Clone period

1-4 hours per pcs usually, kindly refer to the product size for specific time

| Standard accuracy | ±0.3% (deviation is ±0.3mm when size smaller than 100mm) |

| Minimum wall thickness | Wall thickness should be at least 0.75mm to ensure correct filling of the mold. To ensure best performance, we suggest minimum thickness of 1.5mm. |

| Maximum size of the parts | The mold size is limited by the vacuum room dimensions (1900×900×750mm) and the volume of the product (maximum volume 10L) |

| Quantity of cloning mold | Maximum 25 times usage for each mold |

| Surface finish | Smooth surface |