Sand dryer

Working Principle

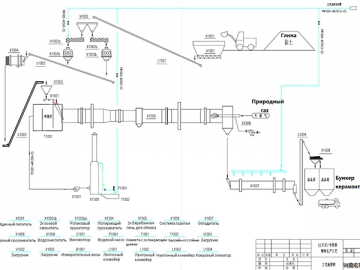

First, sand is delivered into the hopper by the belt conveyor or the bucket elevator. Then feeding device will bring the material from the hopper into feeding pipeline, which further pushes the material to the feed inlet. The pipeline should be slightly more inclined than nature inclination of the sand particles to enable the sand flow into the interior of the dryer.

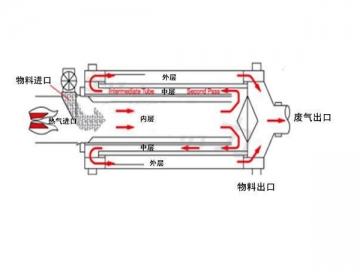

The rotary barrel is slightly inclined in horizontal level. Wet material enters the barrel from the relatively higher end, while heating medium enters from the lower end to form countercurrent contact. Sometimes, the sand and the heating medium come in with parallel flows. Driven by gravity, the sand will move to the lower end during rotation of the barrel. It will be heated directly or indirectly by the heating medium during moving forwards. At last, the dried sand leaves from the discharge chute and then be delivered to next machine or procedure by the belt conveyor or screw conveyor.

The dryer is fitted with shoveling plates in the interior. The plates are supposed to constantly lift the sand and then drop it, thus increasing contact area between the sand and the hot air. As a result, drying efficiency is improved a lot. In addition, the plates also accelerate the motion of the sand. Generally, heating medium can be hot air or effluent gas. After heat exchange, the air or gas will absorb some particles, which need to be extracted by a cyclone dust collector. Sometimes, bag house dust remover or wet dust remover is required for further removing dust from the air.

Characteristics

1. The equipment investment of the dryer is only about 20 percent of similar equipment imported from other countries. It is made of wear-resistant manganese plates which are three to four times higher in wear resistant ability than ordinary steel plates.

2. Our sand dryer is able to reduce water content to less than 0.5 percent from 15 percent. It is a preferable choice for device used for drying of slag powder in cement plants or used in dry-mixed mortar production lines.

3. The thermal efficiency of our sand dryer is 40 percent higher than that of a traditional single-drum dryer.

4. The fuel available include hard coal, soft coal, coal gangue, oil and gas. The dryer can be used for dehydration of granular and powdery material. It is also suitable for drying of lumpy material with size ranging from 20 to 40mm.

5. Compared with a regular single-drum dryer, our sand dryer covers 60 percent less area and reduces construction cost by 60 percent. It also features easy installation.

6. Air leakage is completely eliminated, which means the sealing issue is thoroughly solved.

7. The temperature of finished product is lower than 60 degrees, which make it possible to dump the finished product directly into warehouse without any further cooling process.

8. The temperature st discharge chute is less than 60 degrees, while the temperature of the exhaust gas is smaller than 120 degrees. Low temperature is able to extend the service time of dust removal bags by two times.

9. Coal consumption of the dryer is just one third of that of a single-drum dryer. Electricity consumption is reduced by 40 percent as well. The coal required for drying one ton of sand is less than 18 kilogram.

| Model (mm) | Inclination (%) | Rotating Speed (r/min) | Temperature of Hot Air (℃) | Power (kw) | Capacity (t/h) | Weight (t) |

| 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 | |

| 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 | |

| 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 | |

| 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 | |

| 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 | |

| 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 | |

| 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 | |

| 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 | |

| 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 | |

| 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 | |

| 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 | |

| 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 | |

| 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 | |

| 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |