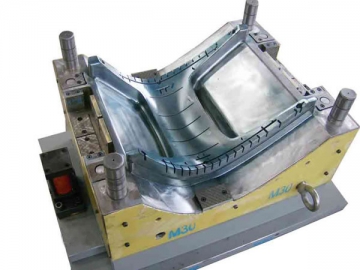

Mold Tryout

If the mold isn't right or problems with the molding process produces defective molded parts, customers can't afford the cost and neither can we. That is why quality inspection is so important to us, helping us point out mold problems before it's too late.

On complex mold tool and part designs, it is quite difficult to make measurements with ordinary hand instruments. Haiyee purchases advanced inspection instruments and testing programs to ensure mold precision and quality. Our expertly trained quality inspection team is skilled in handling these machines to test and try out each mold tooling, so customers can rest assured that they receive quality tools.

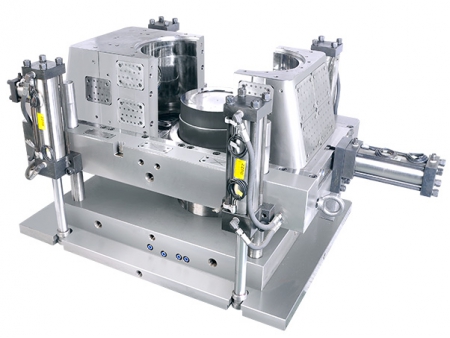

Advanced Measuring Tools

Coordinate measuring machine

Optical projector

Altimeter

Depth gauge

Hardness measuring machine

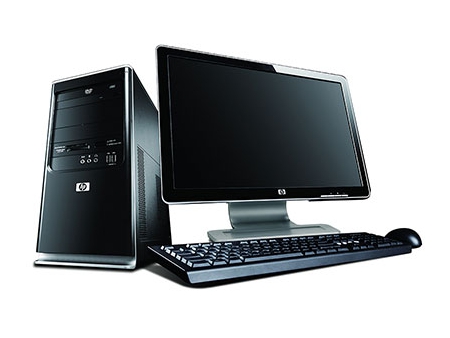

Reverse Engineering

For customers who do not provide mold design drawings, we'll measure the dimensions of the molded part provided by clients and reverse engineer their part design. By using CAD, CAM, and CAE, we can create a computer model of the mold.