Industrial Static Elimination Air Blower / ESD Ionizer

Description:

The core component of the VESD industrial static elimination air blower is modular and delivers a powerful static electricity elimination capacity. It features a plug-in structure, resulting in a high degree of convenience for cleaning and maintenance. We can also provide customized products of various specifications according to your needs.

| Model | ||

| Size | 143*115*68mm | 178*145*68mm |

| Boost way | DC pulse | |

| Operating voltage | ±7000V | |

| Ion balance line | Equivalent pulse controls self-balance | |

| Static elimination time | about 1.3S | about 1.0S |

| Ion balance | ±3V | |

| Maximum air velocity | 1.5M/S | 3.0M/S |

| Maximum air flow | 1.5m3/min | 3m3/min |

| Input voltage | DC24V ±5% 0.5A | DC24V ±5% 1A |

| Operating current | 0.25A | 0.3A |

| Operating temperature | 0-50°C, humidity: 35%-65% | |

| Weight | 0.7kg | 1kg |

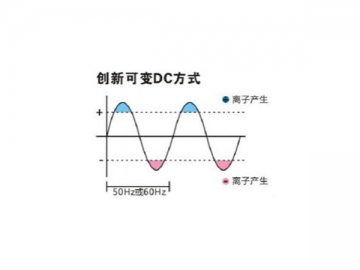

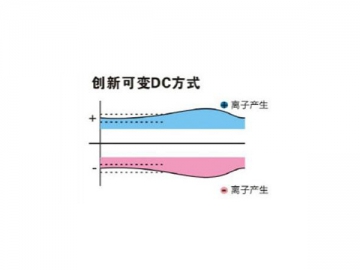

Ionizing air blower is slowly started to apply voltage with low ion discharge.

This ESD ionizer can discharge quantities of negative and positive ions continuously with the ICC circuit to regulate the ion generation of each electrode needle.

With its adjustable pulse mode, the negative and positive ion is generated from each electrode needle. By continuously generating quantities of negative and positive ions, the static elimination is rapid, lasting and stable, forming an ion balance.

Features

1. The static electricity elimination effect is obvious and the positive and negative ion balance is stable even for long term use.

2. Multiple ESD ionizers can be fixed together according to the need of production setup, which is flexible and easy.

3. The plug-in structure design makes it convenient to clean, maintain and operate, and the dust is removed completely to eradicate secondary pollution to the production environment.

4. With the abnormal discharge detection circuit, when an atypical discharge is detected, it can cut off the high voltage power supply while sounding an alarm.

5. The high voltage needle frame is modular, so you need only to replace the accessories rather than to scrap the whole machine.

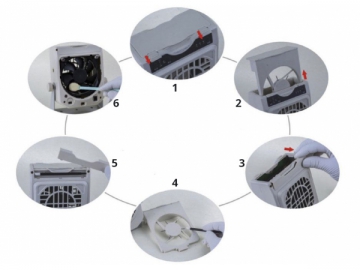

1. Open the locking device at the both ends on the top of the product.

2. Pull up the high pressure ionizing needle frame.

3. Open the cover at the top of blower back side, and take out the swabs.

4. Use clean swabs that will not drop fiber to press the tip of each needle in turn.

5. Put the swab back on the upper back of the air blower and cover the rear cover.

6. Open the rear windshield cover and wipe the air blower blade with a large sponge swab.

Index

static eliminator, air ionizer, air fan, industrial electrostatic control