PPR Hot and Cold Water Pipes and Fittings

PPR Hot and Cold Water Pipes

Kingbull is your trusted supplier of PPR hot and cold water pipes and fittings. Our PP-R pipes for hot and cold water supply are the random copolymer of propylene and ethylene made using advanced gas polymerization process. It makes about 5% ethylene in the molecular chain of PP random copolymer, with approximately 140℃ melting point, 130℃ vicat softening point, 270kj/cm2 tensile strength and 8kg.cm/cm impact strength.

Although our PPR pipes have slightly lower impact strength than PP-B, they come with the best combination property due to excellent resistance to long-term creep. To illustrate, they can be surely used for 50 years in hot water at a temperature of less than 70℃. Therefore, they are ideal for the hot and cold water piping system in buildings.

Applications

The PPR hot and cold water pipes are widely used for industrial and civilian hot and cold water piping system as well as heating system.

| Item | Spec.(mm) | Pack(m/bunch) |

| 20×3.4 | 180/300 | |

| 25×4.2 | 140/200 | |

| 32×5.4 | 80 | |

| 40×6.7 | 60 | |

| 50×8.3 | 40 | |

| 63×10.5 | 24 | |

| 75×12.5 | 16 | |

| 90×15.0 | 12 |

| Item | Spec.(mm) | Pack(m/bunch) |

| 20×2.8 | 180/300 | |

| 25×3.5 | 140/200 | |

| 32×4.4 | 80 | |

| 40×5.5 | 60 | |

| 50×6.9 | 40 | |

| 63×8.6 | 24 | |

| 75×10.3 | 16 | |

| 90×12.3 | 12 | |

| 110×15.1 | 8 |

| Item | Spec.(mm) | Pack(m/bunch) |

| 20×2.3 | 180/300 | |

| 25×2.8 | 140/200 | |

| 32×3.6 | 80 | |

| 40×4.5 | 60 | |

| 50×5.6 | 40 | |

| 63×7.1 | 24 | |

| 75×8.4 | 16 | |

| 90×10.1 | 12 | |

| 110×12.3 | 8 | |

| 125×14.0 |

| Item | Spec.(mm) | Pack(m/bunch) |

| 25×2.3 | 140/200 | |

| 32×2.9 | 80 | |

| 40×3.7 | 60 | |

| 50×4.6 | 40 | |

| 63×5.8 | 24 | |

| 75×6.8 | 16 | |

| 90×8.2 | 12 | |

| 110×10.0 | 8 | |

| 125×11.4 | 4 |

Colors: Available in Green, Orange, White and Gray Colors as well as Bicolor

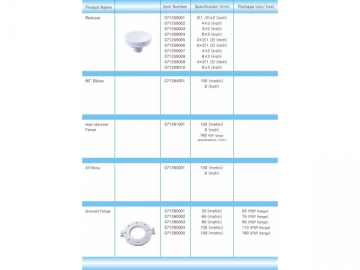

PPR Fittings

-

Elbow -

End Cap -

Reducer -

Tee -

Cross -

PPR Flange Core -

PPR Bypass Bend -

Male Threaded Elbow -

Female Threaded Elbow, Wall Mounted -

Shutoff Valve -

Metal Flange -

Female

Union -

Female Adaptor -

Female Tee -

Female Threaded Elbow -

PPR Union -

Coupling -

Reducer -

Male Union -

Male Adaptor -

Male Tee -

90° Reducing Elbow -

Reducing Tee -

Flange Adaptor

PP-R Tool

PPR die head comes with large taper that is convenient for heat fusion. Teflon coating is applied to avoid sticking of material in welding.

Our PPR welding machine requires a moderate temperature for welding, which is at 260±10℃.

- PPR Welding Machine and Die Heads

- PPR Pipe Cutter

Why Kingbull PP-R Pipes and Fittings?

1. Superior Raw Materials

Kingbull’s PP-R pipes and fittings are made using the premium imported materials from Borealis AG, KPIC, etc. or domestic materials from Yanshan Petrochemical. These materials are free from any addition of reclaimed materials, with national standard GB17219compliant sanitary performance and stable quality.

The melt flow rate (MFR) of the raw materials from which Kingbull PPR pipes and fittings are made is within 0.2-0.35g/10min (230℃, 2.16Kg). International standard≤0.5g/10min. (See table 1 for the physical properties of PPR pipe materials)

| Physical properties | Unit | Kingbull PP-R raw material | Testing method | |

| Density (23 ℃ ) | Kg/m3 | 0.91 | ISO1183 | |

| MFR (230 ℃ /2.16KG ) | g/10min | 0.25~0.31 | ISO1133 | |

| Pendulum impact strength | 23 ℃ | KJ/m2 | No cracking | ISO179 |

| 0 ℃ | KJ/m2 | No cracking | ||

| -30 ℃ | KJ/m2 | No cracking | ||

| Tensile yield strength | N/mm2 | 24 | ISO527 | |

| Elastic modulus | N/mm2 | 850 | ||

| Vicat softening temperature (10N) | ℃ | 132 | ISO306/A | |

| Melting point (DSC curve ) | ℃ | 132 | ISO3146 | |

| Linear expansion coefficient | mm/m·K | 1.5×10-4 | DIN53752 | |

| Thermal conductivity | 0.24 | DIN52615 | ||

2. Cutting-Edge Technology

Kingbull cooperates with universities to continuously improve and update PP-R pipes production techniques.

1) By means of improvement of dies, materials and process, the production speed is increased to 18m/min, and molten plastic stays for a very short time in the extrusion machine, thus ensuring less loss of performance.

2) PPR pipes and fittings are brittle at low temperature. To handle this, we use unique process and formula to remarkably improve the low temperature impact resistance of our PPR pipes.

3) With scientific cooling and shaping process, we make our PPR water pipes approved in 8760 hours continuous testing.

3. Advanced Production Equipment

1) Our extruder comes with BM barrier screw which ensures excellent solid-liquid separation and plasticizing effect, small extrusion output, pressure and temperature fluctuation, great exhaust performance and stable quality of molten plastics. Equipped with KIV forced feeding system, it features fast extruding speed. This ensures that the molten materials stay in the extrusion heads for a very short time, therefore maintaining less loss of performance.

4) Laser diameter measuring instrument is used to test the outer diameter of pipes. It accounts for a high dimensional stability.

5) A high speed PPR pipe cutter imported from Italy ensures rapid, chip free cutting, ensuring flat and smooth end face and preventing notch stress concentration after cutting.