Trimming machine

Aluminum Tube Making Trimmer

Description

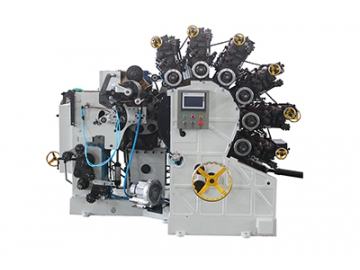

The XSC01 aluminum can making trimmer is also called trimming without burrs which is the professional equipment of the aluminum can manufacturing plant.

The cylindrical shape delivered by the cold extrusion press is pushed into the expansion shaft of the surface finishing trimmer by the conversion suction drum. The tail cutting knife cuts the extra parts in the tail of the cans automatically. And the waste collection box collects all of the excised debris of the can tail into fertilizer bucket. The polishing wheel which operates with high speed finishes the polishing of the can automatically. Then the polished aluminum cans are blown down to the discharge conveyor and enter the next process.

This XSC01 machine is controlled by PLC and has frequency control. It can both be connected with the production line and operate independently.

Technical Parameters| Applicable can diameter | φ35-φ53mm |

| Maximum applicable can length | 250mm |

| Maximum production speed | 120/min |

| Main motor power/total power | 4KW/12.85KW |

| Intake pressure | 0.6MPa |

| Dimensions | 2940*2600*1820mm |

| Total amount | about 2.8 ton |

- The aluminum can making trimmer adopts Siemens PLC control and text display to display the instant production speed and some other information while it is operating.

- This machine adopts closed structure and is equipped with dust suction bucket which all can prevent the aluminum powder caused by the polishing entering the surroundings greatly. This kind of design not only reduces the security risks but also is conducive to the cleanness of the operating environment. The waste collection box collects the excised debris of the can tail into fertilizer bucket.

- The trimming without burrs takes advantage of the mold misalignment and combines the machine tool linkage principle to realize the one-time resection. The incision is very flattening without glitches. The machine is very efficient and has great accuracy.

- The detection system controls the work of the polishing wheel automatically and it will give way when there's no aluminum cans. The replacement of the polishing plate is very convenient and fast.

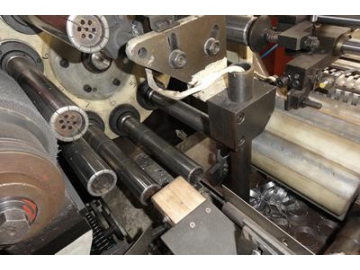

This machine adopts the expansion shaft and the replacement of the mandrel is very fast.

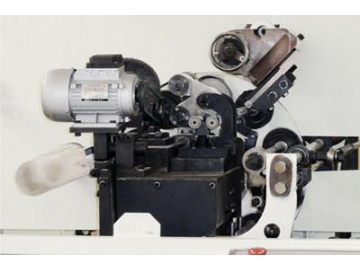

Dust suction bucket

Dust suction bucket  Expansion shaft

Expansion shaft