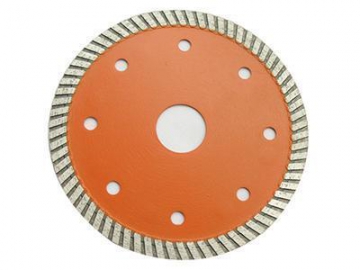

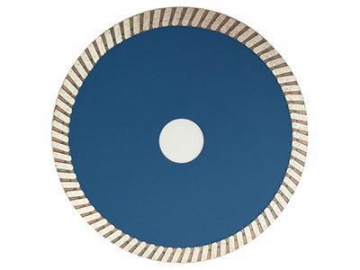

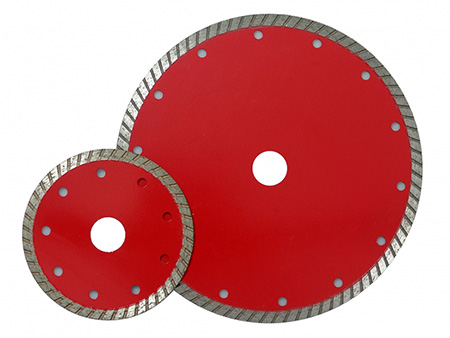

KCC205 Diamond blade (Sintering Process, Turbo Rim Diamond Blade)

The ceramic tile dry cutting saw blade is applied to cutting ceramics, all kinds of tile, marble slate, granite etc. it can be used for dry cutting but has higher cutting speed and longer service life under wet cutting conditions.

1. The ceramic saw blade is strictly manufactured and tested as the EU certification EN13236 standards, and thus the safety performance of product is well guaranteed.

2. The segment using high quality diamond and pre-alloyed powder has stable quality and the cost is reduced.

3. Adopting hot-press sintering process, the close combination between diamond formulation and steel core is realized, thus the diamond saw blade is compact and sharp and has high cutting speed.

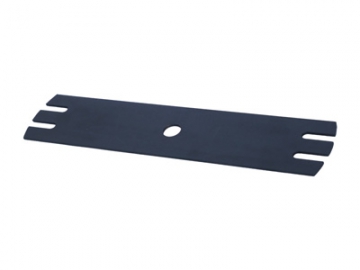

4. Made of high precision steel substrate, it cuts stably and smoothly without dithering under high speed cutting, and broken edge is not easily to appear.

| Item No. | Diameter (mm) | Segment thickness (mm) | Segment height (mm) | Inner hole (mm) |

| | 105 | 1.4 | 8 | 20/22.23 |

| | 115 | 1.4 | 8 | 22.23 |

| 125 | 1.6 | 8 | 22.23 | |

| | 150 | 2.0 | 8 | 22.23 |

| | 180 | 2.0 | 8 | 22.23 |

| | 200 | 2.1 | 8 | 25.4 |

| 230 | 2.3 | 8 | 22.23 |

LIKN Tools offer a wide range of industrial cutting, drilling, grinding and polishing tools, specialize in manufacturing all kinds of diamond cutting and grinding tools for ceramic tiles, porcelain tiles, concrete floors, marble floor, reinforced plastic composite, etc. With over 20 years' experienced team in making industrial tools, we are offering durable diamond tools with competitive prices.

Index

tile saw blade, diamond blade, ceramic cutting blade, porcelain tile blade