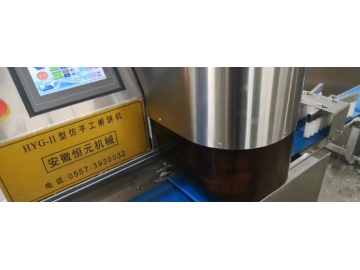

Dough Forming Machine

As a leading bakery equipment manufacturer, we offer snack food makers an extensive range of biscuit production lines and various individual biscuit machines for the line. The dough forming machine presented on this page is one of the essential food machines for our biscuit production line. It is used to cut dough into chunks or smash it, then press them into dough sheets, and finally form biscuit shaped dough.

This dough forming machine is composed of a series of food processing equipment such as laminator, three-color dough sheeter, large dough conveyor, three gauge roll feeder, gauge roller unit, rotary molder, double color wire cut machine, belt type salt and sugar sprinkler, and liquid egg spraying machine.

- Vertical Laminator

- Cut-sheet Laminator

- Horizontal Laminator

The dough sheet laminator is a type of food machinery with stainless steel construction. It is divided into a vertical laminator, horizontal laminator and cut sheet laminator. The cut sheet laminator makes sure that each dough sheet can be scattered with powder, improving quality and taste of hard biscuit. This laminator is important food processing equipment for fermented soda biscuits.

Technical Parameter of Cut-sheet Laminator

| Items | Specifications |

| Power supply | 3-380V, AC |

| Motor power | 12Kw |

| Laminating layers | 4-10 layers (adjustable) |

| Thickness of laminated dough sheet | 2-15mm (adjustable) |

| Powder scattering device | Stainless steel mesh belt type powder scattering machine (or double-roll powder scattering machine) |

| Control type | User interface control, frequency control, single machine control, joint control |

| Control motor for sheet cutting | Japan Sanyo servo motor. |

| Operating method | Touch screen |

| Electrical device brand | France Schneider |

| Housing material | δ 2mm 304 stainless steel |

| Transition support board material | 304 Stainless steel |

- Three-color painting machine

- Three-layer dough sheeter

The three-color dough sheeter is used for making three layer and three color dough sheets and conveying them to the next process. If it is not used for making three color biscuits, you can directly feed dough into the dough sheeter.

The large dough sheet conveyor is used for receiving the dough sheets transported from the feeder.

Our dough forming machine comes with a three gauge roll feeder which is used for feeding dough sheets transported from the top side.

Technical Parameter

| Items | Specifications |

| Calendaring thickness range | 3~30 mm |

| Adjustment method of roll seam | Adjusted by motor-driven screw lifting device |

| Control method | Frequency control of motor speed |

| Roller material | Chilled alloy |

| Operation method | Touch screen |

| Converter brand | French Schneider |

| Housing material | Stainless steel |

Molder

Through this gauge roll unit, the prefabricated dough sheets will be made into the required thickness. Rolling speed and transporting speed of each individual gauge roll can be independently controlled, ensuring easy and flexible operation.

Technical Parameter

| Item | Specifications |

| Calendaring time | 3 |

| Roller diameter | φ 320mm |

| Calendaring thickness range | 0.3~20 mm |

| Control method | Frequency control of motor speed |

| Roller material | Chilled alloy |

| Roller bearing brand | Japan NSK |

| Operation method | Touch screen PLC frequency converter, with memory and breakdown feedback function |

| Converter brand | French Schneider |

| Housing material | Stainless steel |

| Transition support board material | Stainless steel |

Roller Cutting Machine

The roller cutting machine is used for cutting out biscuits. It is composed of a porcupine or embossing roller and a cutting roller. It features high speed and low noise, and can meet the requirement for maximum production capacity.

- Feeding from the second floor

- Rotary moulder

Soft dough will be directly fed into the horizontal rotary molder after being rolled in the roll feeder. The endless belt ensures a 100% qualified rate. It features dual power with frequency control. Distance between feeding rollers is adjusted by hand wheel.

Technical Parameters

| Items | Specifications |

| Motor number | 2 |

| Wrap angle adjustment method | Adjustable |

| Operation method | Touch screen |

| Converter brand | French Schneider |

The wirecut machine can be used with different biscuit production lines. It carries out joint control and single control by advanced frequency converter, and feature fast cutting speed, high production capacity and excellent quality.

The belt type salt and sugar sprinkler is mainly used for sprinkling salt and sugar powder on to the biscuits. To be specific, salt, sugar, sesame and other materials can be conveyed out of the hopper by belt and then sprinkled on the biscuits after scattered. The quantity of salt and sugar to be sprinkled is adjustable. The sprinkling quantity can be adjusted relying on the speed of the belt conveyor.

Technical Parameters

| Speed control method | Frequency control |

| Converter brand | Japan Panasonic |

| Conveyor material | PVC belt with conducting bar |

| Cover & frame material | Stainless steel |

- Segregating unit

- Rim charge recycler

- Syrup and liquid egg spraying machine