Food Process Extruder with Twin Screw

- ModelSX65-IIIA

- Installed Power 35KW

- Actual Consumption 28KW

- Main Power 22KW

- Throughput 120-150kg/h

- Dimension2.5×1.0×1.8m

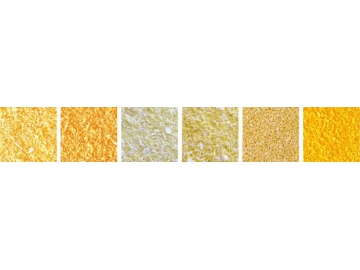

- ProductsFried or Unfried Food

- ModelSX65-I

- Installed Power 60KW

- Actual Consumption 45KW

- Main Power 30KW

- Throughput 150-200kg/h

- Dimension3.5×1.0×1.8m

- ProductsPet/ Protein/ Snack Food

- ModelSX90-II

- Installed Power 115.9KW

- Actual Consumption 55KW

- Main Power 90KW

- Throughput 800-1000kg/h

- Dimension6.0×2.5×3.5m

- ProductsPet/ Protein/ Snack Food

- ModelSX65-IIIB

- Installed Power 35KW

- Actual Consumption 28KW

- Main Power 22KW

- Throughput 120-150kg/h

- Dimension3.5×1.0×1.8m

- ProductsFried or Unfried Food

- ModelSX85-II

- Installed Power 78KW

- Actual Consumption 55KW

- Main Power 55KW

- Throughput 300-500kg/h

- Dimension4.0×1.2×3.0m

- ProductsPet/ Protein/ Snack Food

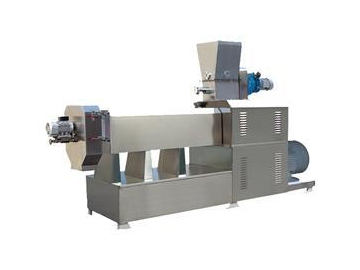

Main feature

- The food process extruder with twin screw produced by Luerya is made up of a feeding system, extrusion system, rotary-cut system, heating system, drive system, cooling system and control system.

- Frequency control delivers strong power and stability. It is used in the feeding system, driving system and rotary-cut system.

- To ensure safe operation of the extruder, it was designed with self-lubrication and forced cooling systems.

- Food process extruders with twin screws have single screws and twin screws in two feeding systems, users can choose according to raw materials. It can feeding evenly and work stably and reliably.

- The screw was treated with a nitriding process, increasing its durability.

- Different draw ratios of the screw can meet different technological requirements.

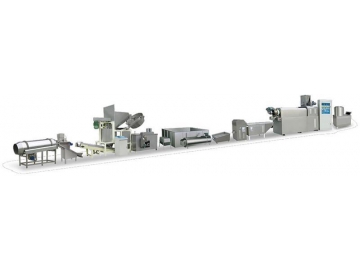

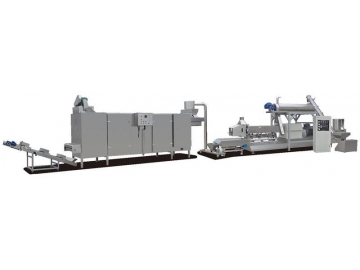

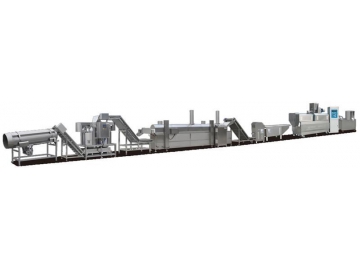

The food process extruder with twin screw can be combined with other equipment to form a food production line

1. Mixer → Food process extruder with twin screw → Post-extrusion cutter → Elevator → Automatic frying machine → Automatic seasoning equipment is used in

2. Feeder → Food process extruder with twin screw → Post-extrusion cutter → Automatic frying machine → Automatic seasoning equipment is used in

3. Mixer → Food process extruder with twin screw → Filling machine → Multi-function shaping machine → Big elevator → Three layers electric oven → Automatic seasoning equipment is used in

4. Mixer → Food process extruder with twin screw → Blower → Hot air direr → Sheeter → Dryer → Elevator → Spreader → Hot air bulking machine → Sugar coating machine → Sugar melting bowl → Dryer is used in

5. Mixer → Food process extruder with twin screw → Dryer → Packing machine is used in recycled rice production line.

6. Mixer → Screw elevator → Food process extruder with twin screw → Vibrating cooler → Blower → Dryer → Cooling machine is used in

7. Mixer → Screw elevator → Food process extruder with twin screw → Traction cutting machine → Elevator → Dryer → Elevator → Pulverizer → Vibrating screen selecting machine is used in

8. Mixer → Food process extruder with twin screw → Blower →Three layers electric oven → Pulverizer → Mixer is used in

Index

food equipment, snack machine, biscuit manufacturing machine, fried food processing