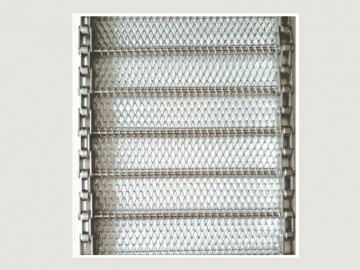

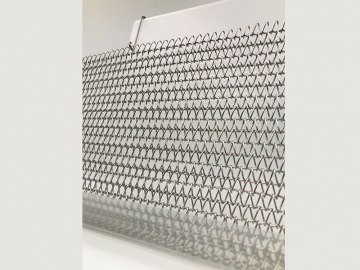

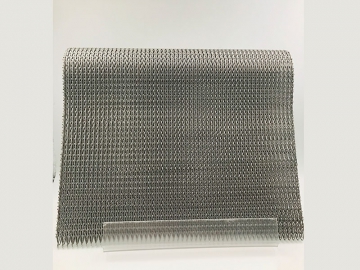

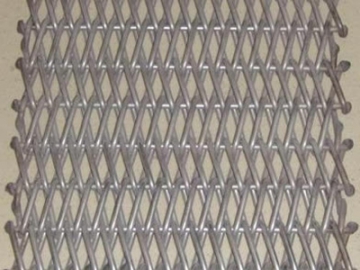

Conventional weave belts

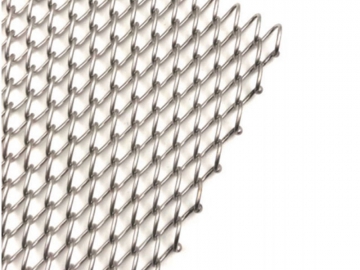

The Conventional weave belts also known as Single Weave belts and Chain link belting, refers to the diamond shape pattern of the belt. This is a metal conveyor belt consists of series of right-handed helix and left-handed helix. The belt is usually used with chains and rods, adopts food grade stainless steel, resistance to high temperature.

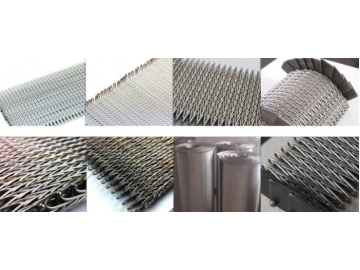

The characteristics of the belt are excellent flexibility, easy cleaning and installation. They are mainly used in food production lines and electronics product production lines.

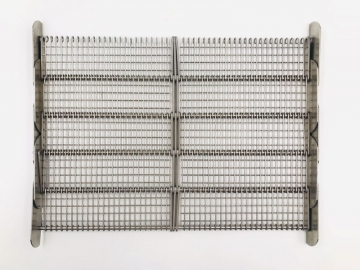

- The installation of cross flights and side plates on both sides of belts can be adjusted according to the requirements of customers.

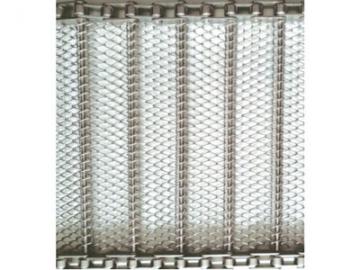

- Metal horizontal rod can be added to the joint of the helixes of the conventional weave belt to improve the strength of it. Thus the upgraded conventional weave belt can be rod reinforced belt.

Application

- Cleaning Belt;

- Drying Belt;

- Freezer Belt;

- Sterilization Belt;

- Metal Conveyor Belt.

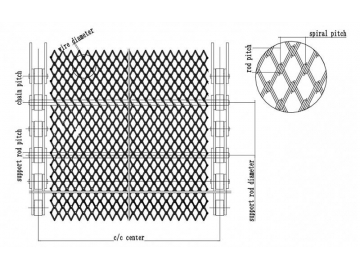

Parameters

| Material | Carbon steel, 304 stainless steels, 316 stainless steels |

| Wire diameter (mm) | 1.2, 1.4, 1.5, 1.6, 1.8, 2, 2.5, 3 |

| Spiral pitch (mm) | 6-40 |

| Rod pitch (mm) | 5-30 |

| Belt width (mm) | 200-5000 |

Note: above are common specifications, other specifications can be customized according to customer requirements.

Characteristics

- Conventional weave belts adopts food grade stainless steel, which is safe and durable;

- The wire mesh of the belt is smooth and can bear high load and tensile strength;

- Conventional weave belts is easy to clean;

- The conveyor belts offer good ventilation;

- The conveyor belts are driven by roller chain sprocket to ensure the service stable and avoid being scratched;

- The dismantling and maintenance of roller chain driven mesh belts are convenient and timesaving.

Related products

Send Message

Most Recent

More

Other Products

Videos