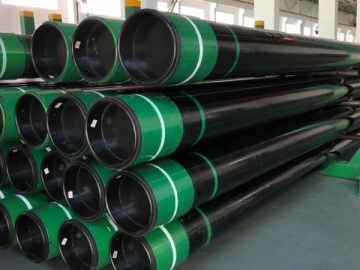

Casing

Casing

In addition to producing high performance andlow cost API compliant casing products, we at Fastube also continually work to bring new products to the market to satisfy ourcustomers’ demands. FT series casing of H2S corrosion resistance, high anticollapse casing, and high grade ERW casing are some of our newly developedproducts, which can be used in a variety of geological conditions.

The seamless casing blank is made by advanced Accu-Roll precision rolling machine, which greatly improvesthe anti-collapsing performance of tubing. In addition, our patented jigs andfixtures such as pipe end inner and outer support device, toolbar strengtheningdevice help enhance pipe clamping rigidity, reduce clamping distortion,eliminate cutting vibration, and thus, improve thread quality.

Fastube ERW casing achieves good welding performance as a result ofcontinued focus on increasing casing welding impact by improving parameterssuch as casing extrusion and welding angle. In fact, the impact value of theERW casing is nearly the same as base metal.

Features such as even wallthickness, smooth thread surface, no stressconcentration area, great tensile, anti-collapsing and sealing performance havemade Fastube casing the product of choice forcustomers worldwide.

Applications

Casing is a large diameter pipe typically used in oil or gas wells toprevent collapse of their walls or boreholes. It is generally assembled andinserted into a recently drilled section of a borehole and held into place withcement. The utilization of casing can help prevent wellbore from separating stratum, ensure high density drilling fluid to continuedrilling deeper and provide a smooth internal bore for installing productionequipment, which greatly facilitates the drilling process.

There are different types of casing used in oilfield exploitationoperations.

1.Surface casing: It is installed with a casinghead on the top to hang and support subsequent casing at each zone. Surfacecasing can be used to isolate freshwater zones and so prevent them from beingcontaminated by drilling fluid.

2. Intermediate casing: It is used to isolate zoneswith different pressures as well as complex strata likely to collapse and leak,so as to install anti-burst device and anti-leakage device in the well.

3. Production casing: It is used to protect productionzone, and provide tunnel for transporting oil and gas.

TechnicalSpecifications

| Spec. | Outside diameter | Wall thickness | Type of end finish | ||||||||

| Ⅰ | Ⅱ | mm | inch | mm | Steel grade | ||||||

| H40 | J55 K55 | M65 | L80 C95 | N80 1, Q FT80T FT80TT | C90 T95 FT90T(TT) FT95T(TT) | P110 FT110T FT110TT | |||||

| 4-1/2 | 9.50 | 114.30 | 0.205 | 5.21 | PS | PS | PS | - | - | - | - |

| 4-1/2 | 10.50 | 114.30 | 0.224 | 5.69 | - | PSB | PSB | - | - | - | - |

| 4-1/2 | 11.60 | 114.30 | 0.250 | 6.35 | - | PSLB | PLB | PLB | PLB | PLB | PLB |

| 4-1/2 | 13.50 | 114.30 | 0.290 | 7.37 | - | - | PLB | PLB | PLB | PLB | PLB |

| 4-1/2 | 15.10 | 114.30 | 0.337 | 8.56 | - | - | - | - | - | - | PLB |

| 5 | 11.50 | 127.00 | 0.220 | 5.59 | - | PS | PS | - | - | - | - |

| 5 | 13.00 | 127.00 | 0.253 | 6.43 | - | PSLB | PSLB | - | - | - | - |

| 5 | 15.00 | 127.00 | 0.296 | 7.52 | - | PSLBE | PLB | PLBE | PLBE | PLBE | - |

| 5 | 18.00 | 127.00 | 0.362 | 9.19 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 5 | 21.40 | 127.00 | 0.437 | 11.10 | - | - | PLB | PLB | PLB | PLB | PLB |

| 5 | 23.20 | 127.00 | 0.478 | 12.14 | - | - | - | PLB | PLB | PLB | PLB |

| 5 | 24.10 | 127.00 | 0.500 | 12.70 | - | - | - | PLB | PLB | PLB | PLB |

| 5-1/2 | 14.00 | 139.70 | 0.244 | 6.20 | PS | PS | PS | - | - | - | - |

| 5-1/2 | 15.50 | 139.70 | 0.275 | 6.98 | - | PSLBE | PSLB | - | - | - | - |

| 5-1/2 | 17.00 | 139.70 | 0.304 | 7.72 | - | PSLBE | PLB | PLBE | PLBE | PLBE | PLBE |

| 5-1/2 | 20.00 | 139.70 | 0.361 | 9.17 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 5-1/2 | 23.00 | 139.70 | 0.415 | 10.54 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 5-1/2 | 26.80 | 139.70 | 0.500 | 12.70 | - | - | - | - | - | P | - |

| 5-1/2 | 29.70 | 139.70 | 0.562 | 14.27 | - | - | - | - | - | P | - |

| 5-1/2 | 32.60 | 139.70 | 0.625 | 15.88 | - | - | - | - | - | P | - |

| 5-1/2 | 35.30 | 139.70 | 0.687 | 17.45 | - | - | - | - | - | P | - |

| 5-1/2 | 38.00 | 139.70 | 0.750 | 19.05 | - | - | - | - | - | P | - |

| 5-1/2 | 40.50 | 139.70 | 0.812 | 20.62 | - | - | - | - | - | P | - |

| 5-1/2 | 43.10 | 139.70 | 0.875 | 22.22 | - | - | - | - | - | P | - |

| 6-5/8 | 20.00 | 168.28 | 0.288 | 7.32 | PS | PSLB | PSLB | - | - | - | - |

| 6-5/8 | 24.00 | 168.28 | 0.352 | 8.94 | - | PSLBE | PLB | PLBE | PLBE | PLBE | PLBE |

| 6-5/8 | 28.00 | 168.28 | 0.417 | 10.59 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 6-5/8 | 32.00 | 168.28 | 0.475 | 12.06 | - | - | - | PLBE | PLBE | PLBE | PLBE |

| 7 | 17.00 | 177.80 | 0.231 | 5.87 | PS | - | - | - | - | - | - |

| 7 | 20.00 | 177.80 | 0.272 | 6.91 | PS | PS | PS | - | - | - | - |

| 7 | 23.00 | 177.80 | 0.317 | 8.05 | - | PSLBE | PLB | PLBE | PLBE | PLBE | - |

| 7 | 26.00 | 177.80 | 0.362 | 9.19 | - | PSLBE | PLB | PLBE | PLBE | PLBE | PLBE |

| 7 | 29.00 | 177.80 | 0.408 | 10.36 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 7 | 32.00 | 177.80 | 0.453 | 11.51 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 7 | 35.00 | 177.80 | 0.498 | 12.65 | - | - | - | PLBE | PLBE | PLBE | PLBE |

| 7 | 38.00 | 177.80 | 0.540 | 13.72 | - | - | - | PLBE | PLBE | PLBE | PLBE |

| 7 | 42.70 | 177.80 | 0.625 | 15.88 | - | - | - | - | - | - | - |

| 7 | 46.40 | 177.80 | 0.687 | 17.45 | - | - | - | - | - | - | - |

| 7 | 50.10 | 177.80 | 0.750 | 19.05 | - | - | - | - | - | - | - |

| 7 | 53.60 | 177.80 | 0.812 | 20.62 | - | - | - | - | - | - | - |

| 7 | 57.10 | 177.80 | 0.875 | 22.22 | - | - | - | - | - | - | - |

| 7-5/8 | 24.00 | 193.68 | 0.300 | 7.62 | PS | - | - | - | - | - | - |

| 7-5/8 | 26.40 | 193.68 | 0.328 | 8.33 | - | PSLBE | PSLB | PLBE | PLBE | PLBE | - |

| 7-5/8 | 29.70 | 193.68 | 0.375 | 9.52 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 7-5/8 | 33.70 | 193.68 | 0.430 | 10.92 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

| 7-5/8 | 39.00 | 193.68 | 0.500 | 12.70 | - | - | - | PLBE | PLBE | PLBE | PLBE |

| 7-5/8 | 42.80 | 193.68 | 0.562 | 14.27 | - | - | - | PLB | PLB | PLB | PLB |

| 7-5/8 | 45.30 | 193.68 | 0.595 | 15.11 | - | - | - | PLB | PLB | PLB | PLB |

| 7-5/8 | 47.10 | 193.68 | 0.625 | 15.88 | - | - | - | PLB | PLB | PLB | PLB |

| 7-5/8 | 51.20 | 193.68 | 0.687 | 17.45 | - | - | - | - | - | P | - |

| 7-5/8 | 55.30 | 193.68 | 0.750 | 19.05 | - | - | - | - | - | P | - |

| 7-3/4 | 46.10 | 196.85 | 0.595 | 15.11 | - | - | - | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 0.264 | 6.71 | - | PS | PS |

|

|

|

|

| 8-5/8 | 28.00 | 219.08 | 0.304 | 7.72 | PS | - | PS | - | - | - | - |

| 8-5/8 | 32.00 | 219.08 | 0.352 | 8.94 | PS | PSLBE | PSLB | - | - | - | - |

| 8-5/8 | 36.00 | 219.08 | 0.400 | 10.16 | - | PSLBE | PSLB | PLBE | PLBE | PLBE | - |

| 8-5/8 | 40.00 | 219.08 | 0.450 | 11.43 | - | - | PLB | PLBE | PLBE | PLBE | PLBE |

Material

25Mn2,30Mn2,37Mn5,34Mn6,25Mn2V,33Mn2V,(25~32)CrMo, (26~29) CrMo44 etc.

Fastube is a