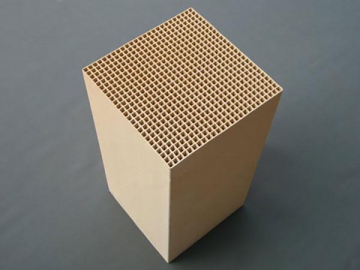

Thermal Storage Honeycomb Ceramic

High temperature air combustion or HTAC is an energy conservation technology developed for combustion systems. Within the HTAC system, a catalyst reacts with CO and HC under 600℃, ensuring a high thermal recovery rate and it minimizes the release of pollutants into the air.

Compared to traditional combustion technologies, the HTAC system minimizes fuel consumption by 20-50%, reduces the oxidation burn loss by at least 20% as well as the NOX release by more than 40%. High efficiency purification and recycling capabilities are both guaranteed.

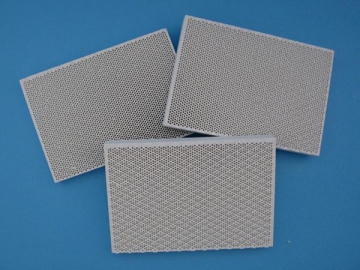

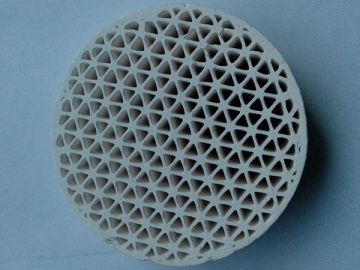

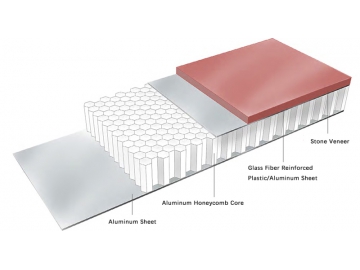

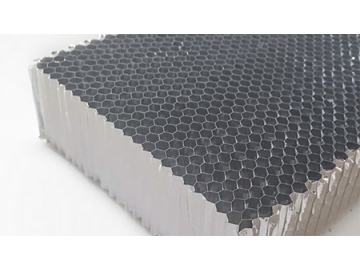

At a temperature of over 2000 ℃, we melt chromium corundum and other high-purity materials to produce our industrial grade honeycomb ceramics, thermal storage balls, and bricks. We produce various types of heat storage media with various hole shapes. The different shapes include square holes, round holes, and hexagonal holes. Wall types include flat surfaces, inclined surfaces, single channel and double channels.

Physical Properties of Heat Storage Media| Properties | Material | |||||

| Cordierite | Cordierite and mullite composite stone | Mullite | Corundum and mullite composite stone | Chromium corundum and mullite composite stone | Fused alumina zirconia and mullite composite stone | |

| Volumetric weight (g/cm3) | 0.6-0.8 | 0.7-0.9 | 0.8-1.0 | 0.9-1.1 | 0.9-1.15 | 0.9-1.15 |

| Coefficient of thermal expansion (20 - 1000℃)×10-6 ·0C-1 | 1.8-2.3 | 4-5 | 5-6 | 5-6.5 | 5-6.5 | 5-6 |

| Specific heat capacity (J ·(g ·K)-1 | ≥0.85 | ≥0.90 | ≥1.0 | ≥1.10 | ≥1.15 | ≥1.15 |

| Thermal conductivity (1000 ℃(w ·(m ·k)-1 | ≥1.0 | ≥1.10 | ≥1.20 | ≥1.20 | ≥1.30 | ≥1.30 |

| Max. usage temperature (℃) | 1250 | 1350 | 1450 | 1550 | 1550 | 1550 |

| Crushing strength of A axis /MPa | ≥20 | ≥22 | ≥22 | ≥25 | ≥30 | ≥30 |

| Crushing strength of B axis /MPa | >8 | >10 | >10 | >12 | >15 | >15 |

| Name | Material | |||||

| Cordierite | Cordierite and mullite composite stone | Mullite | Corundum and mullite composite stone | Chromium corundum and mullite composite stone | Fused alumina zirconia and mullite composite stone | |

| SiO2 | 42-52 | 40-50 | 35-38 | 25-30 | 23-28 | 23-28 |

| AL2O3 | 36-40 | 45-50 | 60-65 | 65-70 | 65-70 | 65-70 |

| MgO | 12-15 | 6-9 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Fe2O3 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| K2O Na2O CaO | <1.2 | <1.2 | <1.2 | <1.2 | <1.2 | <1.2 |

| Size (mm) | Quantity of channels | Wall thickness(mm) | Channel Width(mm) | Surface area (m2/m3) | Void section (%) | Packaging density (kg/m3) | Weight (kg) |

| 150×150×300 | 25×25 | 1.0 | 4.96 | 580 | 68 | 696 | 4.7 |

| 150×150×300 | 40×40 | 0.7 | 3.03 | 891 | 65 | 814 | 5.5 |

| 150×150×300 | 50×50 | 0.6 | 2.39 | 1090 | 63 | 903 | 6.1 |

| 150×150×300 | 60×60 | 0.5 | 1.99 | 1303 | 63 | 932 | 6.3 |

| 150×100×100 | 40×40 | 1 | 2.5 | 784 | 49 | 799 | 1.2 |

| 150×100×100 | 33×33 | 1.1 | 3.0 | 691 | 52 | 750 | 1.13 |

| 150×100×100 | 20×20 | 2.0 | 5.0 | 392 | 49 | 692 | 1.04 |

| 100×100×100 | 40×40 | 1.0 | 2.5 | 784 | 49 | 810 | 0.81 |

| 100×100×100 | 33×33 | 1.1 | 3.0 | 691 | 52 | 750 | 0.75 |

| 100×100×100 | 20×20 | 2.0 | 5.0 | 392 | 49 | 680 | 0.68 |

You may also find products like:

Honeycomb Ceramic, Honeycomb Ceramic regenerator, Heat Storage Ceramic