Synthetic Diamond Grit

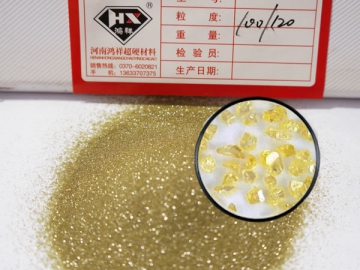

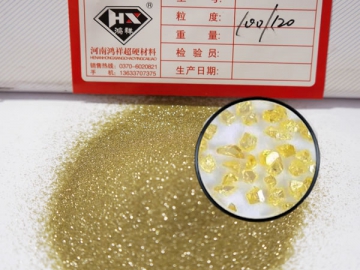

RVD synthetic diamond grit is made from selected, large mono-crystalline diamonds through as a series of processes including crushing, sieving, washing, automatic separation, drying, etc.

Process Flow Diagram

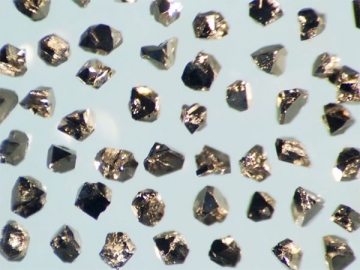

1. Crushing: Large diamond crystals are crushed into small, irregular sizes.

2. Re-crushing: Irregular diamond particles are re-crushed for shape improvement.

3. Sieving: Abrasive grits are sized by sieving and separated into groups of various sizes.

4. Washing: Impurities are removed from the fine diamond grits.

5. Drying: Wet abrasive grits are dried.

RVD man-made diamond abrasives are yellow in color. Most crystals have an irregular shape with a rough surface, rendering them sharp and wear resistant. RVD synthetic diamond grits are excellentindustrial abrasives for grinding brittle material like stone, hard allow, glass and ceramic.

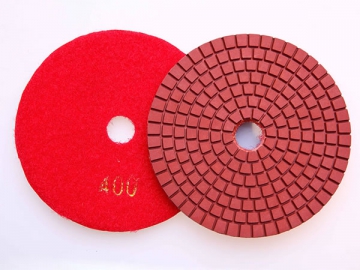

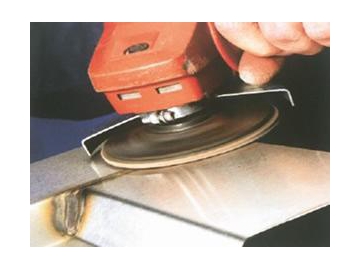

Diamond Abrasive Uses

Major uses for diamond abrasives include resin-bond wheels, ceramic grinding wheels, lapping pastes and electrodes.

| Synthetic Diamond | ||

| International Standards | Chinese Standards | Mesh Size |

| D602 | 30/40 | 30# |

| D426 | 40/50 | 40# |

| D356 | 45/50 | 45# |

| D301 | 50/60 | 50# |

| D251 | 60/70 | 60# |

| D213 | 70/80 | 70# |

| D180 | 80/100 | 80# |

| D151 | 100/120 | 100# |

| D126 | 120/140 | 120# |

| D107 | 140/170 | 140# |

| D91 | 170/200 | 170# |

| D76 | 200/230 | 200# |

| D64 | 230/270 | 230# |

| D54 | 270/325 | 270# |

| D46 | 325/400 | 325# |

| 400/500 | 400# | |

| 500/600 | 500# | |