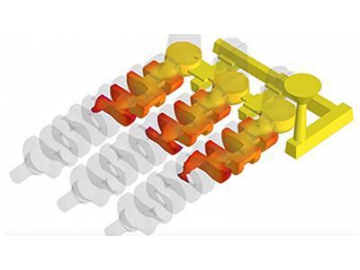

Crankshaft Grinding Machine

CrankshaftGrinding Machine

,1、2

Wheel Dresser

End Dresser

Vertical Stand

Wheel Balancing Machine

Steady Rest

Centering Device

Horizontal Stand

Parallels

Hanging Measuring Device

Polisher

The model of crankshaft grinding machine isMQ8260A-1600, and it is used to grind and repair the crankpin and main journalof the engine crankshaft in automobile, tractor, truck, bus and some otherengineering machinery. It is widely used in the automobile repair center anddiesel engine manufacturing factory.

TechnicalParameters

| Max. Workpiece Swing Diameter × Max. Workpiece Length | Φ580×1600mm | ||

| Capacity | |||

| Max. Swing Diameter Over Table | Φ580mm | ||

| Work Diameter Ground with Steady Rest | Φ30-Φ100mm | ||

| Gyration Radius of Crankshaft | 110mm | ||

| Max. Workpiece Length | In 3-jaw Chuck | 1400mm | |

| Between Centers | 1600mm | ||

| Max. Workpiece Weight | 120kg | ||

| Workhead | Centre Height | 300mm | |

| Work Speed (3 steps) | 25/45/95 r/min | ||

| Wheelhead | Max. Cross Movement | 185mm | |

| Wheelhead Rapid Approach and Withdrawal | 100mm | ||

| Handwheel Cross Feed | Per Turn | 1mm | |

| Graduation | 0.005mm | ||

| Grinding Wheel | Wheel Spindle Speed (2 steps) | 740/890 r/min | |

| Wheel Linear Speed | 25.6-35m/sec | ||

| Wheel Size | Φ900×32×Φ305mm | ||

| Working Table | Table Feed Per Turn of Handwheel | Coarse | 5.88mm |

| Fine | 5mm | ||

| Table Swivel Angle ( △ 18/100) | 1.68 | ||

| Table Swivel Per Unit of Gauge ( △ 1:50) | 10′ | ||

| Total Power of Motors | 9.82kW | ||

| Overall Dimensions (L×W×H) | 4166×2037×1584mm | ||

| Packing dimensions (L×W×H) | 4300×2200×2050mm | ||

| Weight | Approx. 6000kg | ||

| Working Accuracy | Roundness | ≤0.01mm | |

| Cylindricity | ≤0.01mm | ||

| Roughness | Ra0.32μm | ||

Main Accessories

| Jaw Chuck | 2 sets |

| Wheel Dresser | 1 set |

| Wheel Balancing Arbor (Φ80mm) | 1 set |

| Leveling Wedge | 11 sets |

| Wheel Adaptor | 1 set |

| Driving Dog | 1 set |

| Vertical Aligning Stand | 1 set |

| Horizontal Aligning Stand | 1 set |

Optional Accessories

| Wheel Balancing Stand HJX-85-04 | 1 set |

| Hanging Measuring Device | 1 set |

| End Dresser | 1 set |

Note: You need to pay for theoptional accessories if you need them.

Features

1. The workhead of this crankshaft grinding machine takes advantage of belt, and the working speed can be set at 3 values.

2. Cross chucks can be applied by the headstock and tailstock. In addition, theheadstock transmission chain uses friction coupling, and it is convenient foroperation and adjustment.

3. The diameter of wheel spindle is 80mm, and the spindle has good rigidity andstrength.

4. Rolling guide is applied by the wheelhead,and the rapid movement of the wheelhead is controlled by the hydraulic device.

5. The working table moves longitudinally, and the movement can be achieved bypower or manual mode.

6. The lubrications of wheelhead guide rail and bedway arerealized by the automatic cycle process of oil pump.

In addition to this MQ8260A-1600,other models are also supplied including MQ8260A-1800, MQ8260A-2000, MQ8260C,MQ8263, M8240A and HJ049, and they are the same kind of products. Pleasecontact us for samples if you are interested.