ABM Quick Span / K-Span Roll Forming Machine, CS-914-610

Application:

This machine is used for on-site working, and the K-span roll forming machine is often found in construction of warehouses, workshops, airline hangars, ship yards, vehicle factories, and highway guardrails.

Introduction

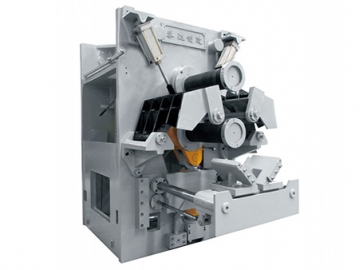

The ABM quick span machine consists of two parts: the forming part and the arching section. These two parts are placed on a mobile frame to move from place to place, earning it the nickname of a mobile factory.

Main Technical Specification of CS-914-610 K Q Span Machine

1. Length: Approx. 10.3 m

2. Width: Approx. 2.25 m

3. Height: Approx. 2.30 m

4. Weight: Approx.13000kg

5. Axle: Three axles, six tires

6. Wheel/tires: Standard

7. Towing: adjustable draw bar height from 80mm-160mm with 80mm round hitch.

8. Lighting System: Easily adaptable lighting

9. Drive System: All hydraulic

10. Fuel tank capacity: 68 liters

11. Construction: All steel and burnished aluminum construction, precision forming rollers with hard chrome plating.

12. De-coiling Device: 508 mm inside diameter, 5000kg capacity

13. Plant: Premium urethane enamel over epoxy primer (white) with buyers' markings on top and side covers

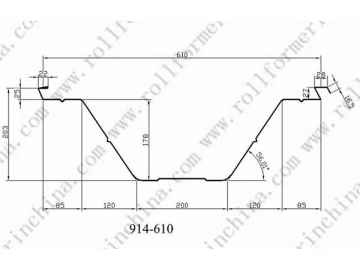

14. Panel forming speed: Approx. 18 meters/min

15. Curving Speed: Approx. 15 meters/min

16. Seaming Speed: Approx. 6 meters/min

17. Tables:four legs, with rollers, stand separately

18. Minimum Radius: 3.65 meters

19. Steel Coil Capacity: 1.2 mm nominal ASTM 653 Grade 50, 1.5 mm maximum thickness, 0.80 mm minimum thickness

20. Maximum Building Size: 33 meters wide, widths are calculated using liberal code parameters from the International Building Code

If you are not familiar with this system, please contact us so we may work out the best solution for you.

This arch roof also includes a number of advantageous features including:

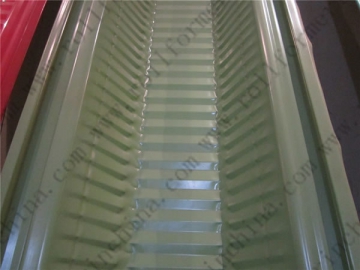

1. A self-supporting roof: There is no need for columns or supports. The roof sheets are locked in place using a seaming machine.

2. Cost savings: This building requires no mounting of screws and bolts, and the roofing system is secure enough for construction.

3. Labor savings: Compared to traditional buildings, it takes only a small group of people to complete the construction of the arch roof building.