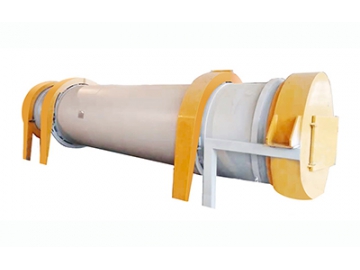

Internal coating machine

Description of Product

In order to meet the using requirements of aluminum tube and ensure the content of aluminum tube is effectively isolated from aluminum, a protective film with stable chemical properties must be sprayed on the inner wall of the aluminum tube. The general coating material is epoxy resin, so this machine is called the inner lacquering machine.

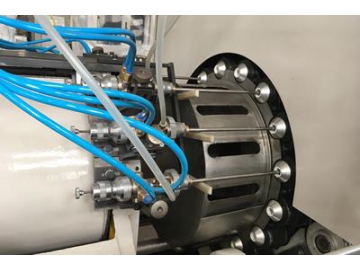

The germ tube output by the annealing oven goes through the conveyor chain and falls into the inlet tube slot and be sent into the rotating cup of spraying machine by. The Fuckson indexer drives the turntable, then the rotating cup enter into the spraying station. The six spraying guns are fixed on the roller, and the gun moves back and forth with the roller while swinging from side to side with the tube chain to complete a working cycle. The gun cycles back and forth, with the tube chain passing through two rotating cups. The single spraying gun sprays every other tube. As a result, each aluminum tube was sprayed three times. In addition, each spraying gun is separately controlled, and the spraying procedure can be set according to user requirements.

When this process is completed, the aluminum tube enters the curing oven along with the transfer chain.

Technical parameter- Suitable diameter of tube: 16-25mm25-35mm

- Suitable length of tube: 180mm

- Production rate: 120 tubes/minute

- Total power: 7KW

- Dimension: 1920×1230×2490mm

- Weight: 3200KG

- Inlet pressure: P=0.5Mpa

- Amount of working position: 31 working positions

- Number of spraying: 3 times

- This PTG01 whole machine is controlled by Siemens PLC to ensure the accurate control of each movement. The indexing uses the Fuckson and is smooth and accurate. The air pressure of each spraying station is accurately controlled by an independent barometer.

- The reciprocating motion of the machine adopts crank mechanism the movement is smooth. The delivery of tube is smooth and also easy to disassemble and transport.

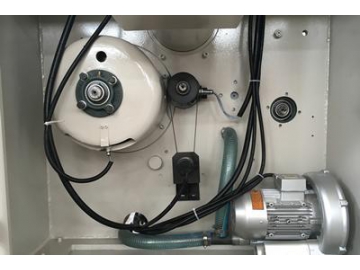

- The main motor is made from Taiwan. The frequency controlled by converter is reliable and convenient. The spraying gun adopts the new type of spraying gun with excellent performance, which developed by our company.

- The good automatic detection system ensures that when there is no tube, the spraying will stop. The tube will stop working automatically when the tube is not good. The text display displays the real-time production information at any time, such as the production speed, the pulse value for the gun running.

- The working system of each gun can be individually programmed and independently controlled to ensure the best spraying effect.

Electrical box

Electrical box  Control panel

Control panel  Spraying gun

Spraying gun  Gas path

Gas path  Driving electric machinery

Driving electric machinery