Internal Lacquering Machine

Internal coating machine

Description

The PTC01 internal lacquering machine is the necessary equipment of the automatic aluminum can manufacturing plant. To satisfy the using requirements of the aluminum can and ensure that the content inside the aluminum can and the aluminum material are separated effectively, the inner wall of the aluminum can is sprayed with a protective film whose chemical performance is very stable. Generally the coating material is epoxy resin.

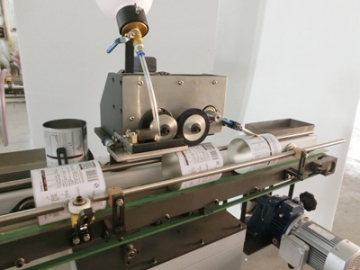

The import system of the aluminum cans send them into the suction drum for can import, the putt pushes the aluminum cans into the sprayer rotor. With the indexing mechanism driving the turntable, the rotor enters the spray station. There are 6 spray guns being fixed on the roller and the spray gun moves to and fro along with the roller as well as swings left and right along with the can chain to finish a cycle of operation. The spray gun cycles once, the can chain passes 2 rotors which means it sprays once every 2 cans. So every aluminum can finishes 3 sprays. Besides, every spray gun is controlled independently and the spray process can be set according to our clients' requirements.

The aluminum can that is sprayed inside then enter the aluminum can curving oven to solidify its coating.

Technical Parameters| Applicable can diameter | φ35-φ53mm |

| Maximum applicable can length | 230mm |

| Maximum production speed | 120/min |

| Motor power/total power | 4 KW/7.85KW |

| Minimum intake pressure | 0.55Mpa |

| Dimensions | 1235*1880*2510mm |

| Weight | 2600KG |

- The PTC01 internal lacquering machine adopts Siemens PLC control to guarantee the precise control of every action. Ferguson indexing mechanism makes sure that the indexing is stable and accurate. All the information is written in both Chinese and English. The air pressure of every spray gun is accurately controlled by independent barometers.

- The reciprocating motion of this lacquering machine adopts crank mechanism. The movement is smooth and has no dead points. The import and output of the cans adopt improved mechanism and the delivery is more smooth and easier for disassembly, installation and transport.

- The main motor adopts Taiwanese products. The frequency converter for adjusting speed is reliable and convenient. The spray gun is Yingrun's newly developed product which has great performance.

- The great automatic detection system guarantees that the lacquering machine won't spray if there's no can. And it stops automatically when meeting malfunction, for example, poor output of the cans.

- The operating process of every spray gun can be set and controlled independently to make sure that the spraying effect is the best.

- The chain rotor tracking spray guarantees that the operating time of the spray gun can be saved to the extreme.

- The text display shows the production speed, the operating pulse of the spray gun and some other producing information at all times