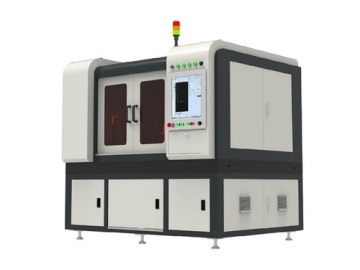

X-6060 Fiber Laser Cutting Workstation

Fiber Laser Cutting Machine / Metal Cutting Machine / Fiber Laser Cutter

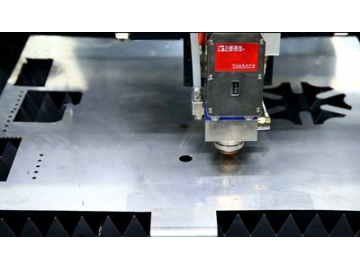

The X series high precision fiber laser cutting workstation offers customized solutions for precision machining needs in order to meet small format, low volume, customized and high precision sheet metal processing needs.

Models and Tech Specs| Model | |

| Cutting Area | 580mm x 580mm |

| X-Y Maximum Simultaneous Positioning Speed | 40m/min |

| Positioning Accuracy | ±0.02mm/m |

| Repeatability | 0.01mm |

| Machine Weight | 600Kg |

| Machine Size | 1300mm x 1800mm x 1850mm (W x L x H) |

| Laser Source | 500W | 700/750W | 1000W |

| Wavelength | Fiber | ||

| Maximum Sheet Thickness* | |||

| Carbon Steel | 6mm | 8mm | |

| Stainless Steel | 3mm | 5mm | |

| Aluminum | 4mm | ||

| Brass | 3mm | ||

| Copper | 2mm | ||

Main Configurations Introduction

Machine Body

The X series fiber laser has a high strength bed, and uses a steel pipe welding structure to ensure a high precision and long term, stable operation.

The fully enclosed architecture provides the best safety features and ensures the exhaust result. A front slide door makes material loading and unloading easy, while the removable side and back door lead to easy maintenance and service.

The working table consists of aluminum strips and clamping devices which can slide in order to help clamp work pieces of different sizes.

The drawer trailers are convenient.

The fully integrated design allows for a high reliability, a small space, and easy transportation. The rotatable console is also able to operate in a convenient manner.

Motion System

The X series fiber laser uses a gantry motion structure. The X-axis beam cast from aluminum materials with a high strength and light weight provides a solid foundation for high performance moving. The ball screw and linear guide achieve a high precision and durability.

The Y axis uses an independent dual drive configuration, allowing for a simple and compact structure with low maintenance costs.

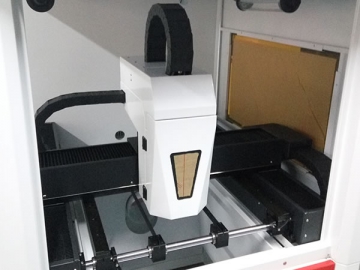

Z Unit

The X series fiber laser cutting machine is equipped with an integrated Z unit for high precision, stability and reliability, as well as a compact design and low maintenance costs.

U Unit

The U unit is an optional component, used to match with pipe metal cutting requirements.

Control and Electronic System

The X series fiber laser is also equipped with a highly integrated, modular electronic system and other control parts from world renowned suppliers. Assembled in strict accordance with international electrical standards, this machine features an excellent performance with outstanding stability and reliability.

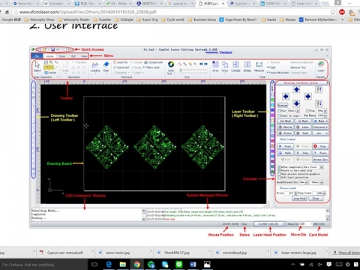

Software

The X series fiber laser is equipped with easy to use software. Using the WYSIWYG design mode and visual control interface, customers can efficiently complete processing tasks, and reduce the difficulty of overall operation.

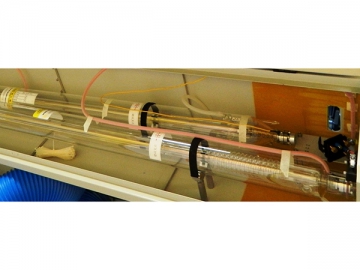

Fiber Laser Source

The X series laser offers a fiber laser source covered under 500-1,000W, from internationally known suppliers. These laser sources feature a high quality, great power stability, low failure rate and excellent service. The model 500W is for thin sheet metal processing, and the model 1,000W is much more efficient for processing thicker materials. Finally, the models 700-750W are both cost effective and flexible.

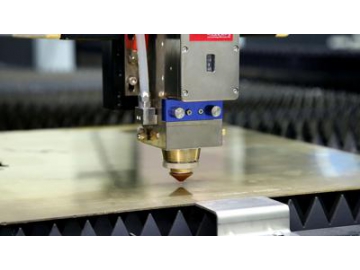

Cutting Head

To ensure the cutting quality, the X series is equipped with a high quality cutting head with the following features:

-- solid and durable mechanical parts

-- high quality collimation and focus lens

-- low energy consumption

-- high accuracy

-- convenient adjustment

-- protection lens

Gas

The X series offers separate control for high pressure and low pressure gas. Users can configure and control the gas according to the material, thickness and processing requirements in order to achieve optimum cutting results.

Cooling System

The laser cutting machine is equipped with a high quality chiller in order to ensure the continuous and stable output of the fiber laser.

Applications