E-4030 CO2 Laser Cutting and Engraving Machine

CO2 Laser Cutting Machine / Laser Cutting and Engraving Machine / Laser Engraving Machine

The E series CO2 laser machine offers a high speed and high quality solution for engraving on acrylic, cardboard, wood and other materials.

Models and Tech Specs| Model | |

| Working Area | 16" x 12" / 400 x 300mm |

| Z-Axis | 6" / 150mm |

| Motion System | High Speed Step Motor, Belt, Linear Guide |

| Positioning Accuracy | ±0.02mm |

| Repeatability | 0.01mm |

| Laser Source | RF CO2 Laser |

| Wattage | 30W |

| Machine Weight | 165lb / 75Kg |

| Machine Size (W x L x H) | 33" x 29" x 19" / 830 x 745 x 470mm |

Main Configurations Introduction

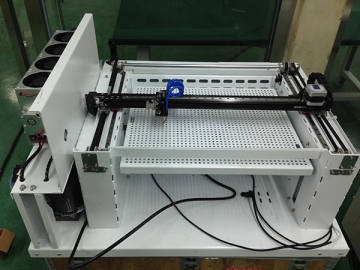

Desktop Sized Machine

The E-4030 is a desktop sized laser machine with a size of 33" x 29" x 19" (830mm x 745mm x 470mm) and a weight of about 165 pounds (75Kg). Its small space allows it to be easily placed on a table or desk for easy operation.

Easy Maintenance

After removing the outer shell, users can see all parts assembled in the internal body, including a motion system, laser system, control, and electronic system. If something goes wrong, it is easy to check, debug and replace parts, as well as other maintenance.

Z Axis

The E-4030 has a working area of 16" x 12’ x 6" (400mm x 300mm x 150mm) in an X Y Z dimension. The working table moves up and down through motor power, in order to hold work pieces of different thicknesses and abnormal shapes in place during the working process.

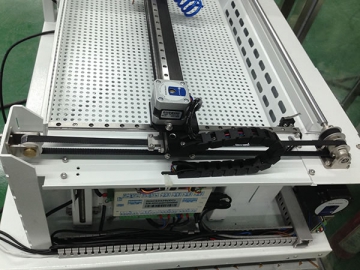

High Performance Motion System

With a high speed motor and belt, the E-4030 laser cutting machine can move quickly, featuring a fast acceleration and response. The high quality linear guide ensures a high precision and durability.

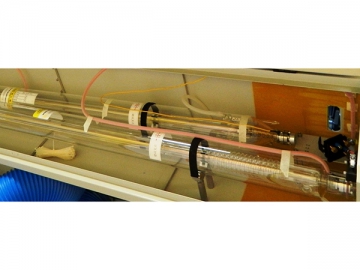

Precise RF Laser

With our RF CO2 laser, users can get more work done with an outstanding processing quality.

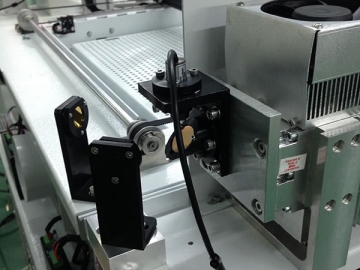

Positioning Laser

By using a coaxial positioning laser to pinpoint borders on engraving work, users can align the work piece quickly and easily, thus reducing the amount of time spent on preparatory work and the number of defective products.

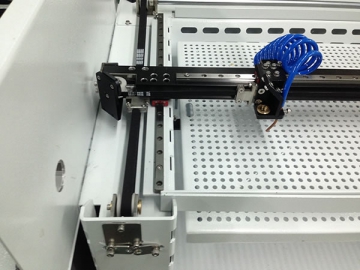

Lightweight Laser Head

With the use of our optimized lightweight laser head, the E-4030 laser engraving machine can engrave at extremely high speeds with a high precision.

High Quality Optics

The E series laser cutting machine is equipped with optics produced in the United States in order to provide a high quality and consistent laser beam across the entire working area, thus achieving a better engraving quality.

Visual Control System

This series of laser cutting and engraving machines is equipped with a high performance control system featuring a user friendly visual UI panel. By embedding flash storage in the controller, users can transfer jobs through a USB drive, Ethernet, or flash disk, then finish the processing offline without relying on a computer connection. With a true color TFT LCD panel, users can also preview machine status and job details before processing, such as the current position of the laser head, connection status, graphic detail, processing parameters and estimated processing time. Users can also adjust the parameters for different materials, as well as run a processing simulation on the panel. The control system will save all changes made for future use. While processing, users will receive real time processing information on the panel, and can adjust parameters on the fly according to actual results. In the event of power failure or mistakes, users can recover the job.

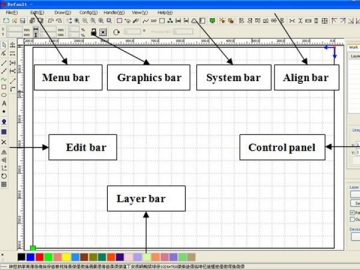

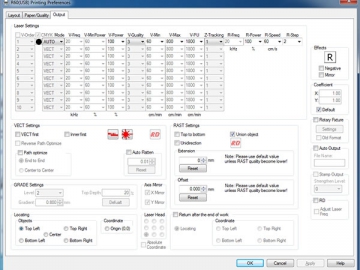

Software and Print Driver

Uses can import or create a new design, finish layout and sorting, run a processing simulation and directly control the machine using our software.

With the user friendly print driver, users can also use their favorite applications, such as CorelDRAW, Photoshop, or AutoCAD to transfer a job to the machine through a few simple clicks.

With layers and a color mapping function, users can assign different processing parameters for different colors in a design. There is no need to run separate jobs for one project, and processing is faster with a more precise laser control.

Safety and Reliability

The E series is designed, engineered and built with safety and reliability in mind. We use electronic parts from internationally known suppliers and build a system to meet international standards. There are numerous sensors around the machine, such as an open door sensor, open laser tube box sensors, laser cooling water pressure sensor and more. The machine will stop automatically if something unsafe occurs. When this happens, users must shut down the machine immediately and completely by pressing the easy to reach emergency stop button on the panel.

Applications