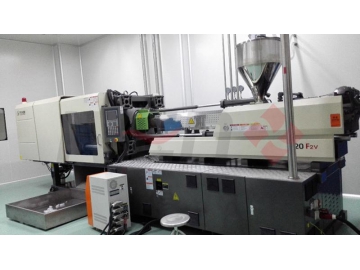

Three Colour Slipper Upper Strap Injection Moulding Machine, EB308D/EB310D

This slipper upper strap injection moulding machine is used to process different materials, like TPR, PVC and PUR and then produce products out of the materials, including single-colour, two-colour and three-colour upper straps. What makes this shoe making machine extraordinary is its ability to hold as many as 10 sets of molds, allowing multiple pairs of slipper straps to be produced simultaneously.

| Item | Unit | | |

| Raw materials | TPR, PVC | ||

| Stations | 8 | 10 | |

| Screw diameter | mm | 50*3 | |

| Maximum injection volume | CC | 390*3 | |

| Injection pressure | MPa | 100 | |

| Clamping force | Tons | 80*2 | |

| Yield | Pairs/hour | 80-200 | |

| Mould space | mm | 360*400*150 | |

| Heating power | kW | 6.5*3 | |

| Total power | kW | 52.5 | |

| Dimensions | cm | 670×260×220 | 700*290*195 |

| Machine weight | Tons | 14.8 | 15.3 |

| Oil consumption | L | 600*2 | |

-

Water cooling system

-

Drying hopper

-

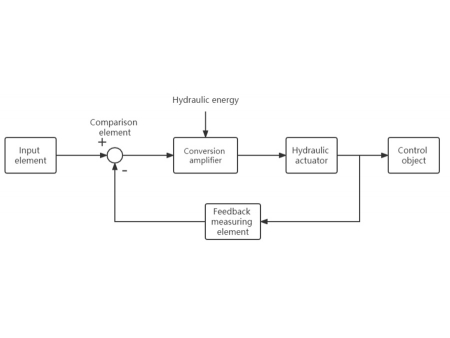

Energy-saving hydraulic servo control system

- Large template design and superior clamping force;

- This injection moulding machine has a block cylinder that can effectively insulate heat and prevent leakage;

-

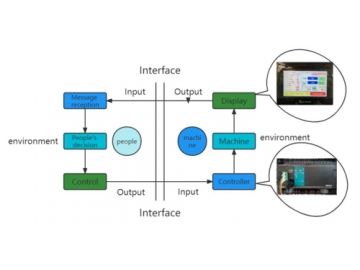

This injection moulding machine for slipper upper straps has a user-friendly PLC control system with industrial human-machine interface (HMI);

-

PLC control system

-

PLC

-

HMI interface

-

-

Mould water cooling system allows for fast formation of products;

-

Servo system is optional to save energy while causing less harm to the environment;

-

Servo system

-

-

Multiple safety measures have been taken, including:

-

Safety sign

-

Emergency stop button

-

Rotary table anti-lifting switch

-

-

Cooling tower can be connected with the footwear injection moulding machine to bring down the temperature of materials;

-

Crusher is used for the recycling of used materials;

-

Vertical mixer is used to mix materials with different colours into the same colour;

| Parts list | ||

| Toolbox | / | 1pc |

| Allen key | 1.5-10 | 9 sets |

| Open-end wrench | 6-24 | 8 sets |

| Phillips screwdriver (small) | / | 2pcs |

| Phillips screwdriver (large) | / | 1pc |

| Adjustable wrench | 250mm | 1pc |

| Heating ring | Ø90*80 mm | 2pcs |

| Heating ring | Ø65*50 mm | 2pcs |

| Heating rod | Ø15.8*100 mm | 2pcs |

| Proximity switch | Ø 25*25mm | 1pc |

| Proximity switch | Ø 12*12mm | 1pc |

| Thermoelectric coupling | K type/5M | 2pcs |

| Oil seal | / | 2pcs |

| Plugging rod | / | 1pc |

| Plugging bushing | / | 1pc |

| Copper gasket | / | 1pc |

| Injection nozzle | / | 1pc |

| User manual | / | 1 |