Screen Protector Film Laminating Machine

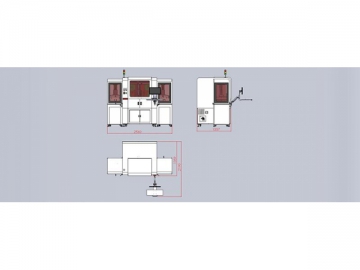

| Items | Parameters |

| Dimensions | L900mm×W600mm×H1500mm |

| Laminating range | L10.26mm×W5.3mm |

| Feeding and discharging | Fully automatic (vibrating disk) |

| Anti-skipping | Vacuum detector alarms while workpiece skipping |

| Locating method | Locating pin |

| Laminating capacity | 2 pcs/time |

| Laminating material | Screen protector |

| Pneumatic elements | SMC |

| Sensor | Keyence |

| Leftover winding | Stepping motor |

| Locating precision | ± 0.02 mm |

| Laminating precision | ± 0.15 mm |

| Laminating method | Sucking laminating |

| Laminating speed | 3600 pcs/hr |

| Power supply | AC 220V 50HZ |

| Air source | 0.5-0.8MPa |

A brief Introduction to Screen Protector Film Laminating Machine

In-house developed, the cylinder type screen protector laminator automatically feeds and discharges materials. In comparison to conventional laminating machines, the screen protector film laminating machine demands one operator and can finish the work that used to be done by 20 workers. In average, the screen protector laminating system handles 3600 workpieces in every hour. Thanks to its high efficiency, stable performance, small occupation, low cost and labor saving, this machine is an optimal choice for mass production of mobile phones.

Attractive Features of Screen Protector Film Laminating Machine

1. The cylinder is fixed firmly, requires no manual adjustment and ensures stable laminating.

2. By using a PLC system and a sensitive touchscreen, the mobile phone manufacture machine possesses convenient parameter adjustment and control, as well as reliable operation.

3. All pneumatic components are from SMC to ensure long lasting performance of the laminating machine.

4. The laminating system automatically alarms when material shortage or workpiece skipping.

5. Workpieces are fixed by pins to avoid displacement while laminating.

6. Laminating speed: 3600 pcs/hr.

7. With the utilization of the screen protector film laminating machine, the qualified rate of finished products is greatly increased.

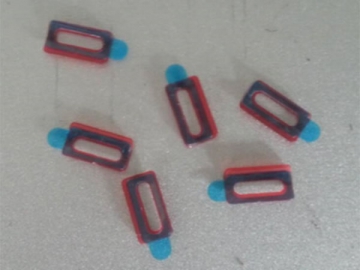

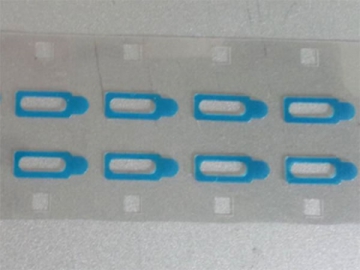

Samples