FPC Laminating Machine

Stiffeners on flexible printed circuit include stamp gum, conductive adhesive, conductive film and steel sheet, to improve the flexibility of circuit boards and strength of the plugging part. With the assistance of this FPC laminating equipment, stiffeners can be pasted on the circuit more accurately and quickly. In comparison to other laminating machines, the flexible printed circuit laminating machine shows great advantages in speed, precision, stability, cost efficiency and adaptability.

Specifications of Flexible Printed Circuit Laminating Machine| Systems | Items | Parameters | Notes |

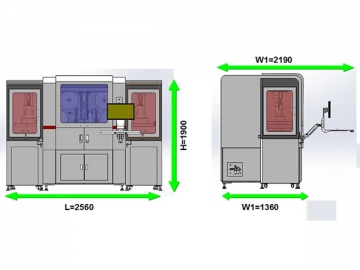

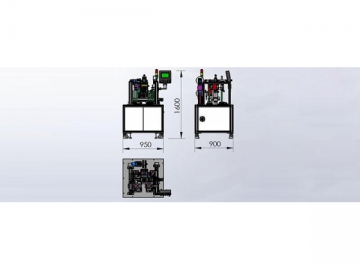

| Mechanical system | Dimensions | L2100 mm×W1600 mm×H1950 mm | |

| Workbench size | 420mm×450 mm | Laminating zone: 500×500 mm | |

| Size of workpiece to be sucked | Max.: 35×35 mm Min.: 3×3 mm | ||

| Weight | 1700 kg | ||

| Power supply | AC 220V 50HZ | ||

| Air source | 0.5-0.8MPa | ||

| FPC feeding and discharging | Fully-automatic | Support paper stacking | |

| Power | 6.5KW | ||

| Workstation | 4 | Two in left side, two in right wide | |

| Number of axis | 12-17 | ||

| Suitable materials | Adhesive tapes, steel sheets, camera lens adhesives, polyimide adhesive tapes | ||

| Vacuum sucking platform | The platform can be changed in accordance with different materials, like FPC, camera lens adhesives, etc. | ||

| X-axis movement | Mitsubishi AC servo motor | ||

| Y-axis movement | Mitsubishi AC servo motor | ||

| Platform rotating | DDR servo motor | ||

| R laminating head rotating | Mitsubishi AC servo motor | ||

| Max. moving speed of X-axis | 730 mm/s | ||

| Max. moving speed of Y-axis | 730 mm/s | ||

| Laminating head rotating | 360 degrees | With heating function (70-150 degrees) | |

| Rotational angle of platform | 360 degrees | With heating function (70-150 degrees) | |

| Leftover winding | Stepping motor | ||

| Locating precision | ±0.1 | ||

| Repeat accuracy | ±0.01 | ||

| Locating method | Visual location | ||

| Laminating method | Sucking laminating | ||

| Software system | Programming method | Three-point locating, MARK locating, scan locating, CAD input | Easy and convenient operation |

| Operation interface | Easy operation | ||

| Main control system | Computer | Intel dual-core CPU, 2GDDR memory, 500G hard disk | Reliable data process |

| Display | 19-inch color liquid crystal display | Clear display | |

| Power supply | AC 220V 50HZ power: 7KW | ||

| Control system | Computer control panel | Computer-controlled operation | |

| Visual location system | Camera | CCD pixel: 5 million | |

| Registering | CCD registering, easy and convenient | ≤15min | |

| Light source for upper camera | Radial pattern light, adjustable luminance | Red light adjustable | |

| Light source for lower camera | Strip pattern, adjustable luminance | Red light adjustable |

Technological Features of Flexible Printed Circuit Laminating Machine

1. Online programming is easy and convenient.

2. The appearance design is original and the operation design is user-friendly.

3. Precise and advanced machine parts include ball screw, servo motor, photoelectric elements, guide rails, optical scale and compensation device.

4. Adopting imaging pre-detecting technology, the laminating solution guarantees excellent lamination quality.

5. The flexible printed circuit laminating machine is highly uniform and suitable for different materials.

6. CCD registering function is provided.

7. Vacuum sucking technology is applied in the whole process.

Advantages of Flexible Printed Circuit Laminating Machine

1. Both motion control system and visual identity system gained independent intellectual property rights.

2. A slightly adhesive tape is used to feed material, easy and reliable.

3. A set of FPC laminator replaces 8-10 workers, allowing for high-precision production.

4. FPC boards are automatically transferred in upper and lower sides.

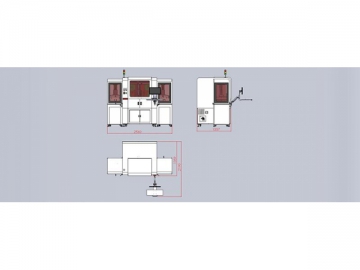

5. The laminating platform is installed with four stations and can rotate 360 degrees, simplifying the process work.

6. Automatic parameter memory function is designed.

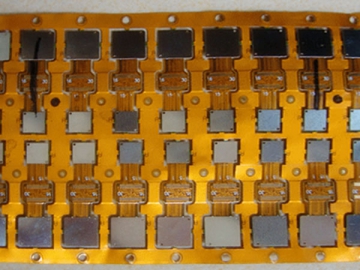

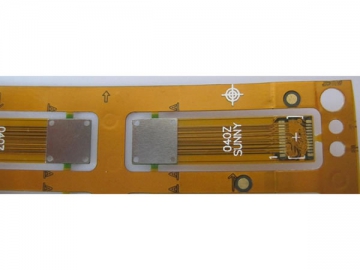

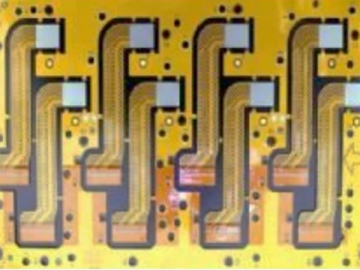

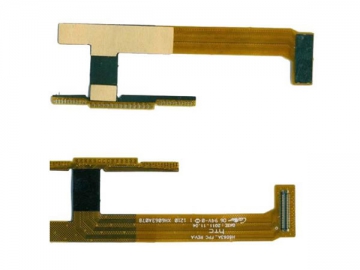

Samples