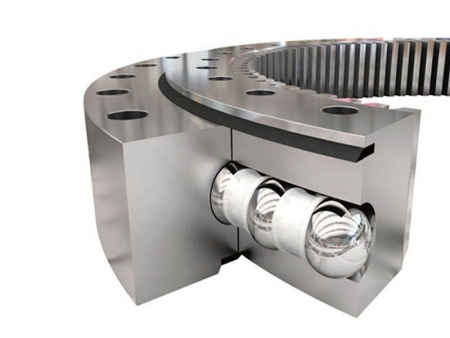

High-Speed Angular Contact Thrust Ball Bearing

Structural features:

Small ball design, with excellent high-speed performance, high stiffness and low heat buildup

The material used for bearing ring is high purity SHX bearing steel, with a special heat treatment process, cold treatment process and material modification technology, greatly improve the fatigue life of this series of bearing.

Contact angle offers a choice between 30º (as in BAR series) and 40º (as in BTR series). Ball bearings in special widths are available. The bearing outer dimensional deviation is intentionally adjusted in order to create a clearance between the ball bearing and the pillow block it fits in. The result is no radial load acting on the ball bearing, only axial load is allowed; The assembly method is back to back installation.

Using the ball guided nylon cage, can long-term work stably less than 120ºС.

The rolling element include: Steel ball (BAR10S;BTR10S) and ceramic ball (BAR10H; BTR10H)

Speed factor:

BAR10S series

Grease lubrication DmN≤750000 that the limiting speed N≤750000/Dm Dm—Bearing mean diameter

Oil (minimum quantity) lubrication DmN≤950000

BTR10S series

Grease lubrication DmN≤650000 that the limiting speed N≤650000/Dm Dm—Bearing mean diameter

Oil (minimum quantity) lubrication DmN≤850000

BAR10H series

Grease lubrication DmN≤850000 that the limiting speed N≤850000/Dm Dm—Bearing mean diameter

Oil (minimum quantity) lubrication DmN≤1050000

BTR10H series

Grease lubrication DmN≤750000 that the limiting speed N≤750000/Dm Dm—Bearing mean diameter

Oil (minimum quantity) lubrication DmN≤950000

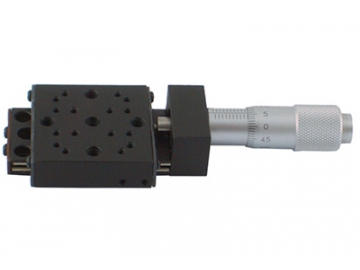

Applications:

Using with cylindrical roller bearing, mainly used for high-speed and high axial precision rotation and other conditions.

For example:

big wheel spindle of CNC universal grinding machine, CNC lathe spindle, centerless grinding wheel shaft, bearing raceway grinding wheel spindle, high-speed precision machinery, etc.

Model Selection