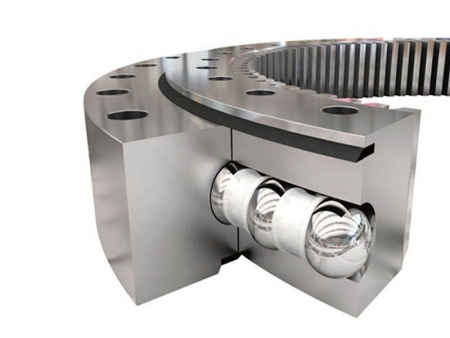

High-Speed Angular Contact Ball Bearing

Structural features:

High speed series LYZYC with small ball design

The material used for bearing ring is high purity bearing steel made in Europe, with a special heat treatment process, cold treatment process and material modification technology, greatly improve the fatigue life of this series of bearing.

The contact angle include 15º and 25º, the paired use can bear both axial load and radial load or synthetic load.

Using the outer ring guided phenolic resin bakelite cloth cage, can long-term work stably less than 80ºС.

There are two types of rolling elements:

Steel ball (H719, H70); Ceramic ball (HC719,HC70)

For the middle-high speed working conditions, is recommended to use steel ball;

For the high speed and special working conditions, can use ceramic ball.

Speed factor:

When the rolling element is steel ball (H719, H70)

Grease lubrication DmN≤1200000 that the limiting speed N≤1200000/Dm Dm—Bearing mean diameter

Oil (minimum quantity) lubrication DmN≤1800000

When the rolling element is ceramic ball (HC719,HC70)

Grease lubrication DmN≤1400000 that the limiting speed N≤1400000/Dm Dm—Bearing mean diameter

Oil (minimum quantity) lubrication DmN≤2200000

Applications:

Mainly used for high-speed and high-precision rotation and other conditions.

For example:

CNC machining center spindle, high-speed electric shaft for grinding, grinding wheel spindle, high-speed precision machinery, etc.

Can provide sealed bearings with preinstalled grease.

Model Selection