Beer and Breweries Separator

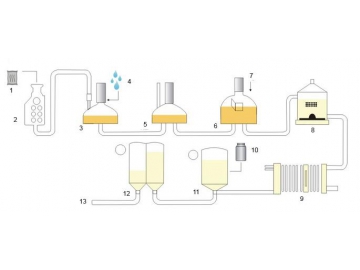

We provide high performance separator of disc stack structure for beer clarification. The disc stack separator can achieve high-precision beer filtration with membrane filtration method, it is able to separate heavy solids in beer by means of rotating bowl. Beer separation equipment can help breweries to produce clarified beer quickly with no loss of aroma or carbon dioxide.

Separator applications

- Beer clarification

- Green beer clarification

- Yeast elimination

- Hot wort separation and beer recovery

- Breweries clarification

- Alcohol Separation and purification

Parameters

| Model | Capacity (L/H) | Motor Power (KW) | Bowl Speed (RPM) | Inlet Pressure (Mpa) | Outlet Pressure (Mpa) | Weight (kg) | Dimension (mm) |

| NZDR604 | 1500 | 2.2 | 8800 | 0-0.1 | 0.1-0.3 | 280 | 800X600X900 |

| NZDH206 | 3000 | 5.5 | 7000 | 0-0.1 | 0.1-0.3 | 480 | 990X930X980 |

| NZDH207 | 5000 | 7.5 | 6080 | 0-0.1 | 0.1-0.3 | 680 | 1120X910X1225 |

| NZDH211 | 10000 | 15 | 5500 | 0-0.1 | 0.1-0.3 | 1080 | 1200X1150X1420 |

| NZDH213 | 15000 | 18.5 | 5300 | 0-0.1 | 0.1-0.3 | 1280 | 1250X1200X1500 |

| NZDH415 | 20000 | 22 | 5100 | 0-0.1 | 0.1-0.3 | 1680 | 1300X1300X1650 |

The capacity above is only for reference, the actual situation depends on material properties of customers.

Customization instructions- The parameters of centrifuge in the table above are standard. Centrifuges can also be customized according to your requirements.

- You need to provide parameters including material properties, separation accuracy and other special requirements for your selection of centrifuges.

Related products

Send Message

Most Recent

More

Other Products

Videos