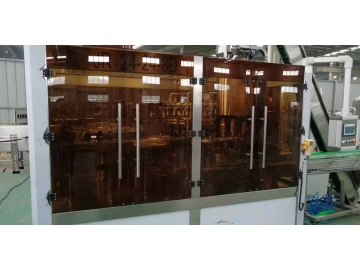

3-in-1 Automatic Beer Bottling Machine

Request a Quote

Monoblock Rinsing, Filling and Capping Machine for Breweries and Wineries

Jinrong is a Chinese trusted manufacturer of beer bottling equipment. We can produce and supply a full range of automated filling equipment. Whether you're interested in monoblock rinser-filler-capper machine or complete beer bottling line, we will take time to listen and produce what you require at competitive pricing.

Videos

Basic Information

- Bottle type: PET bottles, glass bottles

- Cap type: plastic screw caps, crown caps

- Bottle volume: 200-2000ml

- Washing method: adopting newly developed mechanical valve that precisely controls the rinsing fluid, without leakage of water

- Filling method: isobaric filling system

- Capping method:

Plastic cap: magnetic clutch capping head is used for closing of plastic screw caps, the torque is easily adjustable for reliable cap closing quality

Crown cap: capping force can be easily adjusted, ceramic material is used to protect caps from being damaged

Specifications

| Model | Production output (500ml PET bottle) | Overall dimensions (L×W×H) | Power | Weight |

JR18-18-6DB | 1500 b/h | 2800×2050×2200mm | 3 kW | 6000 kg |

JR24-24-8DB | 3000 b/h | 3100×2250×2800mm | 4 kW | 7500 kg |

JR32-32-10DB | 5000 b/h | 3600×2900×2900mm | 5.5 kW | 9000 kg |

JR40-40-10DB | 7000 b/h | 4250×3250×2900mm | 7.5 kW | 10500 kg |

JR50-50-12DB | 10000 b/h | 5200×3700×3000mm | 11 kW | 15000 kg |

JR60-60-15DB | 13000 b/h | 6300×4400×3000mm | 11 kW | 18000 kg |

JR72-72-16DB | 17000 b/h | 6900×4950×3000mm | 11 kW | 19000 kg |

JR80-80-18DB | 20000 b/h | 7600×5100×3000mm | 15 kW | 21000 kg |

Features

- This 3-in-1 bottle filling machine is typically used to fill beer into plastic or glass bottles, it combines rinsing, filling and capping functions in one machine;

- CO2 pressure is accurately controlled, with stable liquid level;

- The filling valve specially designed for beer is equipped with pre-evacuation system to remove the oxygen in the bottles prior to filling;

- Bottle centering system enables bottles to be precisely centered and reliably sealed;

- There is no dead corners for sterilization of inlet and outlet openings of filling valve, ensuring the internal filling valve is sterile; The filling valve is equipped with automatic CIP cleaning cup;

- Equipped with PLC control and frequency converter to guarantee highly automatic production and smooth operation, and the touch screen panel enables all settings to be easily accessible;