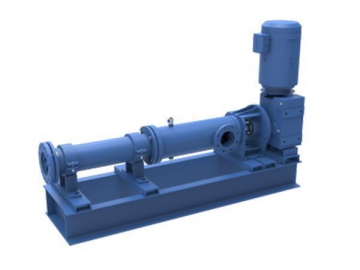

K Class Progressive Cavity Pump

Applications

The K class progressive cavity pump was developed according to the needs of customers with space constraints. The pump body length is shortened to merely 2/3 of standard pumps. This makes the K class pump suitable in shipbuilding, oilfield transportation, offshore platforms or factory applications with tight spaces. The pump is designed to transport mediums with a maximum solid content of 45%, including water.

Parameters

Stage: 1-12 stages

Type: single-head monoblock pump, double-head nonoblock pump

Working pressure

Single-head pump: 6 bar, 12 bar, 18 bar, 24 bar, 36 bar, 48 bar, 60 bar, 72 bar

Double-head pump: 5 bar, 10 bar, 20 bar

| Model | Flow range m3/h | Speed range rpm | Motor power Kw | |

| VD030-028P04OH | 0.3~2.5 | 200~600 | 0.75~1.5 | |

| VD035-060P04OH | 0.4~4 | 200~550 | 1.1~4 | |

| VD040-005P04OH | 2~6 | 150~520 | 1.5~5.5 | |

| VD050-011P04OH | 3~13 | 110~480 | 3~7.5 | |

| VD060-019P04OH | 3~23 | 100~460 | 4~11 | |

| VD070-029P04OH | 5~36 | 100~440 | 5.5~15 | |

| VD090-053P04OH | 10~50 | 100~350 | 7.5~22 | |

| VD100-080P04OH | 15~70 | 80~330 | 15~37 | |

| VD120-120P04OH | 10~90 | 70~290 | 18.5~45 | |

| VD150-230P04OH | 10~120 | 60~230 | 22~75 | |

| VD170-300P04OH | 20~150 | 50~200 | 30~110 |

Working principle

Progressive cavity pumps operate with a positive displacement working principle. The pump utilizes a positive displacement through interference between the rotor in eccentric motion and the fixed rotor. The seal cavities are disconnected and the rotation of the rotor inside the stator. The seal cavities are axially moved from the inlet to the outlet, this creates a pressure differential that results in the medium flowing through the different seal chambers.

- Design drawing of the stator and the rotor

- Metal flexible rod universal joint

- Spring flexible rod universal joint

- Ball tooth universal joint

Rotor

The pump rotor can be produced with varying geometric designs according to customer requirements. Surface hardening or vacuum heat treatments can be applied for metal components. When these are completed, the hardness of the metal can reach HRC 65-67.

Stator

Material: NBR, NBRH, HNBR, EPDM and FKM. The various materials are suitable for different levels of mediums and working conditions.

Universal joint

We can provide customers with universal joint transmission parts that start with traditional pin type and pin sleeve type universal joints and go on to hygiene class, flexible type, ball tooth type and cross pin type universal joints, to deal with various torque transmissions and axial load requirements.

Shaft seal

Packing or mechanical seals can be chosen for the shaft of the pump. The different styles should be selected based on the working conditions of the pump. Cooling and washing systems can be included to extend the working lifetime of the pump.

Driving system

SEW, NORD, ABB and other high quality driving systems can installed on your new pump.

Weifang Subtor as a German Subtor invested company in China, offers wide range of progressive cavity pumps and components. The K class progressive cavity pump has typical applications as water pumping, slurry pumping, oil pumping, etc. A progressive cavity pump is a type of positive displacement pump, also known as eccentric screw pump. With German supported technology and rich marketing resources, Subtor provides quality PCP pumps with custom solutions for global clients.