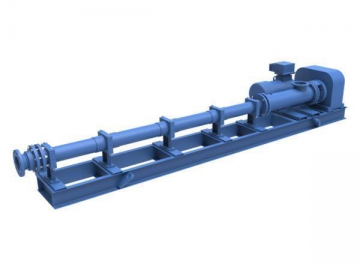

V Class Progressive Cavity Pump

Application

The Subtor V Class progressive cavity pump features a connecting rack and thrust bearing. This type of bearing is designed to bear the axial load during operation in order to protect the deceleration motor from damage. It is suitable for high pressure pumping applications in oil transportation, particularly for long distance operations. The maximum working pressure of the pump is 72 bar and the maximum flow capacity is 300 meters cubed/hour.

The pump can handle any medium including water with 45% or less solid content.

Parameter

Level: 1-12 level

Type: Single/Dual head(s) Progressive Cavity Pump

Operation pressure

Single head pump: 6 bar, 12 bar,18 bar,24 bar, 36 bar,48 bar, 60 bar, 72 bar

Dual head pump: 5 bar, 10 bar,20 bar

| Model | Flow range m3/h | Rotate speed range rpm | Motor power Kw | |

| VD020-009P24OH | 0.1~0.4 | 250~450 | 1.5~3 | |

| VD030-028P24OH | 0.3~1.2 | 250~450 | 4~11 | |

| VD035-060P24OH | 0.5~1 | 250~450 | 11~18.5 | |

| VD040-005P24OH | 1~3 | 250~450 | 15~22 | |

| VD050-011P24OH | 2~8 | 250~400 | 22~45 | |

| VD060-019P24OH | 3~15 | 200~400 | 30~45 | |

| VD070-029P24OH | 5~30 | 200~400 | 55~90 | |

| VD090-053P24OH | 10~40 | 150~350 | 110~160 | |

| VD100-080P24OH | 15~50 | 150~250 | 110~200 |

Operation theory of progressive cavity pump

This progressive cavity pump is a volumetric pump. It operates through the interference fit of the eccentric rotor and the fixed stator, creating an interconnected seal cavity. When the rotor rotates, the sealing cavity moves between the inlet and outlet. This creates a pressure differential that causes the medium to move rapidly through the pump.

- Designed picture of stator and rotor

- Metal flexible rod universal joint

- Spring flexible rod universal joint

- Ball tooth universal joint

Rotor

The rotor can be designed and processed with various shapes according to customer requirements. The metal materials can be specially treated in order to increase hardness to HRC 65-67.

Stator

Material: NBR, NBRH, HNBR, EPDM and FKM are optional.

Different materials are suitable for different levels of working condition.

Universal joint

Various types of universal joints are available for selection, such as pin, hygienic, flexible, ball tooth and cross pin to deal with multiple torque transfer levels and axial loads.

Seal

Packing or mechanical seals are optional. In order to extend the working life of the shaft, a cooling and flushing system can be installed.

Driving system

SEW, NORD, ABB and more high quality driving systems are optional.

Weifang Subtor as a German Subtor invested company in China, offers wide range of progressive cavity pumps and components. The V class progressive cavity pump has typical applications as food pumping, water pumping, slurry pumping, sludge pumping, sewage pumping, wastewater pumping, viscous fluid pumping, etc. A progressive cavity pump is a type of positive displacement pump, also known as eccentric screw pump. With German supported technology and rich marketing resources, Subtor provides quality PCP pumps with custom solutions for global clients.