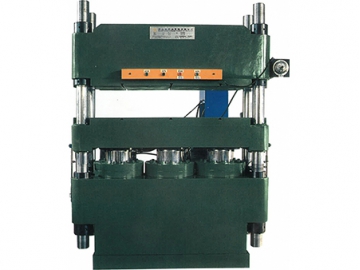

Hydraulic Sand Lime Brick Press

The SH series hydraulic sand lime brick press is the heart of our sand lime brick plant. It is independently developed by Sanhe depending on the market demands. Fully automatic brick placing robot is attached to the press. We have obtained national patent for this new type product. This brick making machine is manufactured using advanced hydraulic control theory as well as up to date foreign hydraulic technology and products, automatic control technology and state of the art mechanical engineering techniques. It is superior over domestic similar products in both quality and performance.

Hydraulic Press System

Main hydraulic components of the sand lime brick press come directly from German Bosch Rexroth. Main and auxiliary pumps are original plunger pumps imported from Germany, ensuring high energy efficiency. Control system applies Siemens S7-300 PLC.

Frame of the hydraulic press, composed of three beams and four columns, comes with a prestressed tube-in-tube structure. It features optimized finite element analysis of prestressed structural members. Robust structure allows it to bear a tensile force of over 2000 tons. The walking beam slides on a flat face. It is mounted with main and auxiliary hydraulic cylinder.

Hydraulic power unit is designed on the basis of the advanced hydraulic control technology in the world and using imported products. This makes it sure that the sand lime brick press can realize pre-pressing, pressing, pressure maintaining and others. In addition, it can precisely control stuffing height and thickness in the mold. Hydraulic oil achieves temperature control in continuous filtration, keeping the hydraulic brick machine in its peak performance. Bricks in different specifications can be made by changing molds.

Fully Automatic Brick Placing Robot

The brick placing robot performs automatic brick clamping, transporting and placing. It is driven by a variable frequency motor and with the help of computer it can conduct multi-layer placing of fresh bricks on the autoclaving carts. The height of each layer of freshly pressed bricks is transferred by encoder to the computer for accurate control. This overcomes the defect of other height measuring devices which are liable to be disturbed. By changing clamps, it can hold bricks in different specifications such as standard bricks, hollow bricks, pavers, etc. Gentle, precise and stable clamping and placing account for a considerable increase of finished products qualification rate.

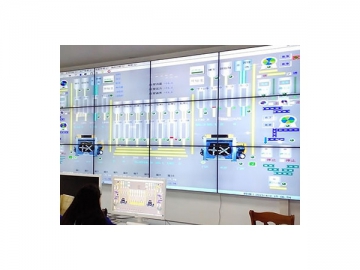

Automatic Control System

The control system uses a Siemens PLC controller. The master switch can be locked. It comes with a 10.4" color touch screen that enables a human-machine interaction.

| Brick types | 24 0 x 115 x 53MM (Standard brick); 240 x 115 x 90MM (Perforated brick); 390 x 190 x 190MM (Hollow brick); Colored paver bricks in various specifications |

| Quantity | 32-36pcs per press (Standard brick) |

| Molding cycle | <16s |

| Production capacity | 7200-9600pcs/hour |

| Nominal pressure | 1100-1250T |

| Pressure head stroke | 500/900MM |

| Power | 75KW (main motor) |

| Degree of automation | Fully automatic |

| Operating mode | 10.4" color touch screen |

| Dimensions | 4785 x 4965 x 4690MM |

| Weight | 80T |