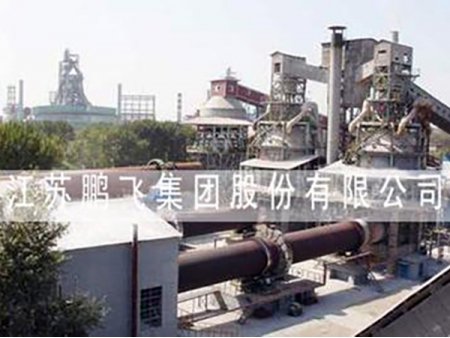

Autoclaved Sand-lime Brick Production Line

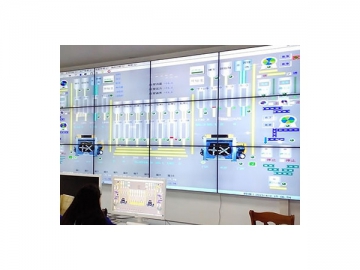

Here at Sanhe, as a prominent manufacturer of building material machinery, we are able to design and manufacture machinery and complete plant for production of sand-lime bricks. Our high quality, efficient and cost effective autoclaved sand-lime brick production line mainly consists of four parts involving materials preparation, dosing and mixing, lime hydration and mixing, pressing and autoclaving.

Production Process of the Sand-Lime Brick Plant

1. Raw materials preparation: Crushing, milling and conveying;

2. Raw materials dosing and mixing: Dosing in an automatic dosing system, mixing in a forced type twin shaft mixer;

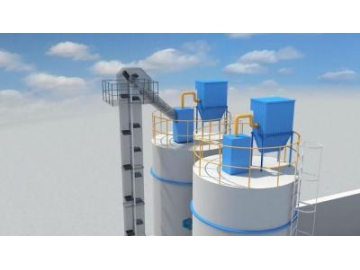

3. Lime hydration and mixing: Continuous lime slaking in a silo, mixing in a hydrated lime mixing machine;

4. Sand-lime brick production: Pressing in a fully automatic brick press;

5. Cubing: Autoclaving to finished products

Advantages of this Sand-Lime Brick Production Method

1. Batch mixing in forced type twin shaft mixer ensures intensive and uniform mixing.

2. Continuous lime hydration meets the requirements of continuous production. Hydration time is easy to be ensured and material bridging in the silo can be prevented.

3. Hydrated mixture is further mixed in a mixing machine, ensuring higher compactness and improved performance. Therefore, the quality of finished bricks will be enhanced.

4. The fully automatic sand lime brick press used in the plant features high automation and capacity, compact structure and low labor intensity. It can produce premium quality bricks and make various silicate products according to market demand.

5. Autoclaving is able to considerably shorten the curing period, thus improving production efficiency and ensuring product quality.