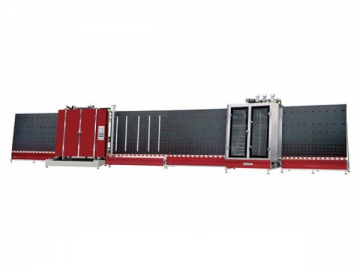

GPL-W Series Digital Insulating Glass Production Line

This GPL-W series digital insulating glass production line adopts an exterior pressing method, and the whole line is solely controlled by a PLC control system and dual touch screen display system. Trajectory and gear are used for glass fastening, which is very stable and reliable. The glass washing machine is equipped with 3 pairs of fur brushes, the glass washing speed can reach up to 10-12m/min, and the spray direction of spray system can be adjusted. It is applicable for manufacturing two-layer insulating glass, three-layer insulating glass, curtain wall insulating glass and special insulating glass.

Parameter

| Model | GPL-XY2500Y-W | GPL-XY2000Y-W |

| Input Voltage | 380V 50Hz | 380V 50Hz |

| Total Power | 33KW | 25KW |

| Cutting Glass Size | 2500×3000mm | 2000×2500mm |

| Min Glass Size | 300×450mm | 300×450mm |

| Glass Thickness | 4~18mm | 4~18mm |

| Working Speed | 8~48m/min | 8~48m/min |

| Total Weight | 7700kg | 7000kg |

| Size of Line | 20000×2600×3530mm | 18000×2600×3030mm |

Show details:

1.Pressing part:

-

- Trajectory and gear are used for glass fastening, which is very stable and reliable.

-

- Pressing machine adopts rectangle frame type structure, which will not make the glass deformation during pressing process.

-

- The glass pressing mechanism structure is made of 2.75mm rectangular steel tube welding process.

-

- Servo drive system makes the controlling process more precise, efficient, stable and reliable.

2.washing part:

-

- The internal components and screws are all made of stainless steel, copper, anti-water alumina, wool fabric and so on, so they are durable and easy to maintain and repair.

-

- The glass washing speed can up to 10-12m/min with 6 high-temperature fur brushes of 180mm diameter and 4 spray equipment.

Features:

- The pressing plates of the coupling press unit can automatically expand and are easy to maintain.

- The glass washing machine is equipped with 3 pairs of fur brushes which are specialized for Low emissivity glass and will not damage the film layer of glass during cleaning process.

- Glass pressing part adopts servo drive system, which is more precise and will not be affected by temperature comparing to traditional pneumatic control system.

- It adopts touch screen as display screen, which can display the temperature and speed of water, production output and so on. And there will be prompt message on the display when equipment errors happen.

- Operators can control the glass transport speed, and this production lie is equipped with a buffer storage area which can minimize the waiting time of operators and increase the production efficiency.

Maintenance

- Clean the equipment every day, and sweep the surrounding environment of equipment.

- Apply lubricating oil to transmission parts.

- Check the electric wire joint of the equipment weekly, identify the points with potential errors.

- Check the screw of transmission part joint monthly and fasten any loose screws.

- Change the lubricating oil for reducer every six months.

- Change the hydraulic fluid for hydraulic pressure system every year.

- Sweep the dust for electronic control system and check the completeness.

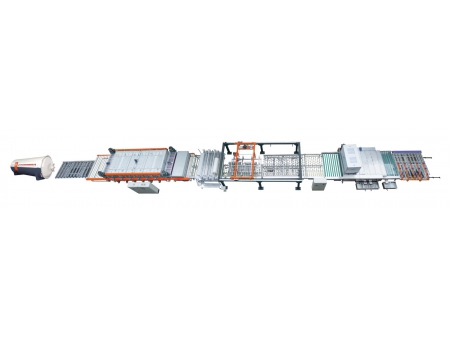

Recommended matched equipment

Related products

Send Message

Most Recent

More

Other Products

Videos