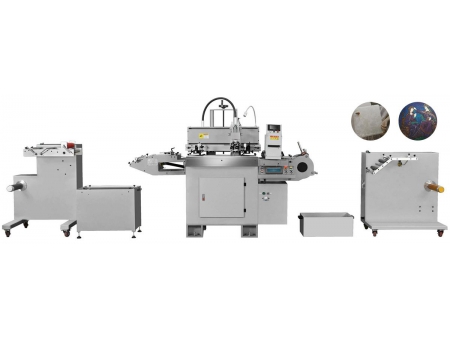

Automatic Non-woven Screen Printing Machine

- FB-NWF-12010-1

Automatic roll to roll nonwoven screen printing machine, single color nonwoven printing machine - FB-NWF-12010-II

Automatic roll to roll nonwoven screen printing machine, two-color nonwoven printing machine - FB-NWF-12010W

The newly developed nonwoven printing machine saves power and space.

The FB-NWF_12010-II two color non-woven screen printing machine was developed in 2011, and can print 2 colors simultaneously. The machine consists of a feeding part, two printers, two IR dryers, and the collection part. This machine uses water-based ink to print on shopping bags.

This machine is an upgraded version of the single-color screen printing machine, and works with a higher precision. With its mesh precision, it’s ideally suited for printing on bags with more than 2 colors.

A single color screen printing machine can continuously print two or three rounds, but the finished product is not as great as the two color printing machine, though both are equipped with photocells.

The single color screen printing machine has a photocell for reading mark and stopping fabric after printing. The two color machine features 2 photocells. One is used after the first printing, and the second is used after the first drying, before the second printing process begins.

Features

1. Feeding, printing, drying and rewinding are all finished automatically. This reduces labor intensity and overcomes weather condition constraints.

2. With its balanced pressure and thick ink, this screen printing equipment is great for printing on high-grade non-woven products.

3. Different sized screen frames can be used.

4. The large printing size formatting allows the screen printing machine to be capable of printing multiple patterns, and improves efficiency.

5. The printing gap has a minimum of1 cm, which reduces material consumption.

6. Transmission and imprinting systems are both controlled by a servo motor, which ensures the printing is precise.

7. With its printing positions being accurate and stable, this non-woven screen printing machine can be used with the cross cutting machine, splitting machine, and non-woven bag making machine to improve production efficiency.

| Model | | ||

| Max. printing size | 1200×1100mm | 1200×1100mm | 1200×1100mm |

| Non-woven roll width | 1250mm | 1250mm | 1250mm |

| Non-woven fabric weight | 45g/m2-100g/m2 | 45g/m2-100g/m2 | 45g/m2-100g/m2 |

| Max. roll diameter | 800mm | 800mm | 800mm |

| Printing speed | 500-1100m/h | 500-800m/h | 500-1400m/h |

| Total power | 380V 3P4N 24KW | 380V 3P4N 65KW | 380V 3P4N 28KW |

| Dimensions | 10500×1800×1720mm | 21500×1800×1720mm | 7500×1800×2200mm |

| Structure | Unwinding - Printing - Drying - Rewinding | Unwinding - Printing - Drying - Rewinding | Unwinding - Printing - Drying - Rewinding |

| Weight | 2000kg | 4000kg | 3500kg |