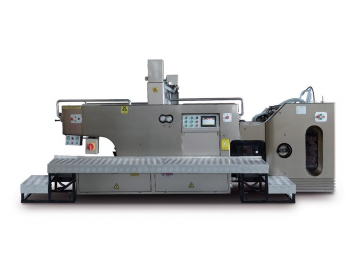

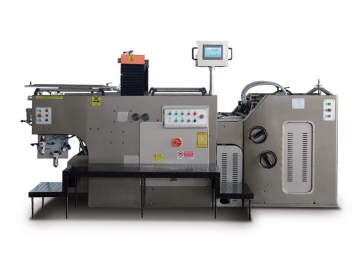

Automatic Stop-Cylinder Screen Printing Machine

The automatic stop-cylinder screen printing machine is an upgraded product, based on the swing-cylinder screen printing machine. In accordance with the cylinder movement form, this flatbed cylinder press is divided into two different press types: a swing cylinder press and a stop cylinder press. The difference is based on if the axis is either mobile or fixed when the cylinder rotates.

This machine features a high automation degree, prints quickly, and accurately overprints with no noise. It is widely used for printing on paper, ceramic, instrument faceplates, and packaging labels.

Features of Stop-Cylinder Screen Printing Machine

1. This machine runs quickly, while still maintaining its precision.

2. It is reliable and durable, making it great for large-sale printing.

3. Overprinting precision is controlled with a PLC system.

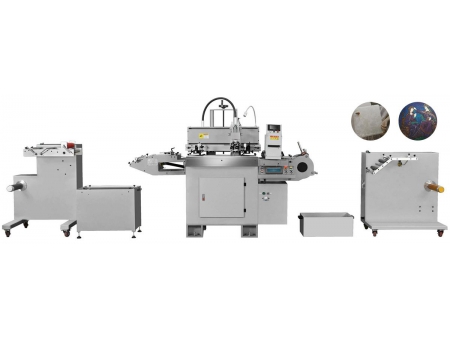

Adjustable lay

Adjustable lay

gauges Withdrawable

Withdrawable

screen

frame Squeegee

Squeegee

pressure

balancing cylinder Pneumatically

Pneumatically

lockable screen

frame Folding paper

Folding paper

output platform Precision

Precision

guide rail

| Model | | |

| Max. paper size | 800×600mm | 1020×720mm |

| Min. paper size | 350×270mm | 560×350mm |

| Max. printing size | 800×590mm | 1020×710mm |

| Paper thickness | 90-250g/m2 | 120-350g/m2 |

| Printing speed | 1000-3300p/h | 1000-3000p/h |

| Screen frame size | 1070×1070mm | 1070×1070mm |

| Power | 11kW | 15kW |

| Weight | 4000kg | 5500kg |

| Dimensions | 4280×2480×1710mm | 4800×2800×1800mm |