Pulsation Dampener

(Dampener for Drilling Mud Pumps)

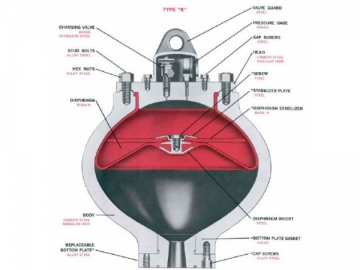

- Bladder Type Pulsation

Dampener - Pulsation Dampener with

Cover - Custom Shape Pulsation

Dampeners

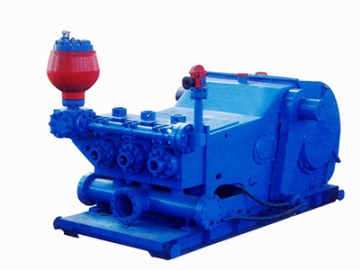

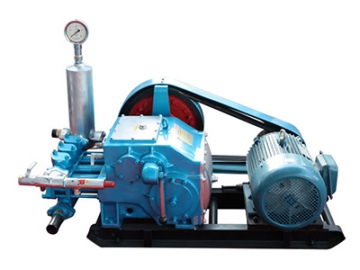

Our pulsation dampener is designed to stabilize the velocity variation of mud pumps, and it is available in several models with displacement and pressure ranging from 1 gallon to 20 gallons and 250 psi to 7500 psi, respectively. For quality considerations, every pulsation damper must pass the hydrostatic test (1000 psi) before shipment.

Feature

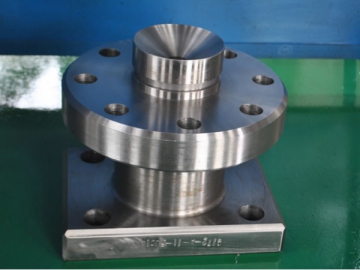

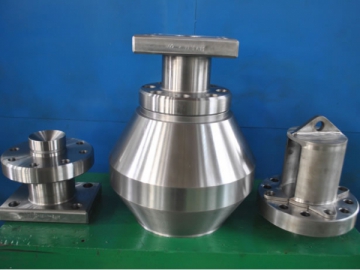

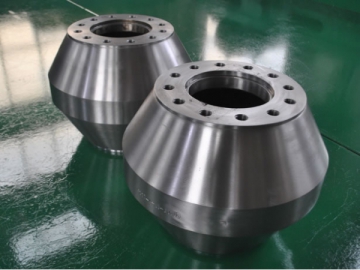

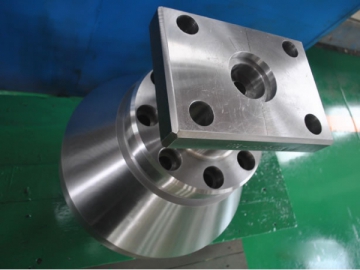

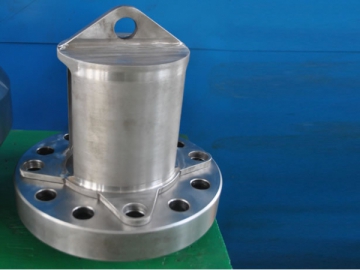

1. The spherical pulsation dampener is manufactured from Q345B alloy steel via one-piece forging and machining processes, creating a uniform, smooth and spherical surface inside the chamber. As a result, fatigue failure and other annoying problems generated during welding and casting are avoided, while the performance, service life, operation safety and reliability of our product are all improved greatly.

2. Thanks to the one-piece spherical design, our pulsation dampener boasts high efficiency despite of its small body, and it doesn’t need any extra structural support. In this regard, our discharge pulsation control equipment exhibits better piping flexibility when compared with appendage style dampeners.

Typical Application

1. Suction Stabilization

When mounted on the upstream of mud pumps, the pulsation dampener can stabilize fluid that is going to flow into pump cylinders, thereby protecting valve body, valve seat, piston and other pump parts from premature damage caused by cavitation.

On the other hand, if installed near the inlet or suction flange of mud pumps, it could help to ensure complete filling of cylinders during each stroke.

2. Pulsation Dampening

Pressure waves or fluctuations at the discharge side may lead to fatigue failure of cylinder, valve body, valve seat, downstream pipe and other major components. Under this condition, our surge dampener could be installed close to the discharge flange to alleviate pressure fluctuations, thereby extending the service life of downstream components and equipment.

3. Surge Pressure Absorption

The sudden start up of pumps and sudden closure of valves tend to result in pressure surge in piping system, and this phenomenon, commonly referred to as water hammer, may damage downstream pipes, pipe supports and other equipment.

Given this, our pulsation dampener should be mounted at a proper location to absorb impact energy so as to protect expensive downstream equipment.

4. Energy Storage

As a result of its special structure, our pulse reducing pulsation dampener could work as an accumulator in hydraulic systems. More specifically, an appropriately sized pulsation dampener is able to store energy for a short time, and this is exceptionally meaningful for lubrication systems because an interruption in lubrication oil supply will lead to disastrous consequence for downstream equipment.

5. Special Application

Our pulsation dampener also fits for pressure compensation of hydraulic systems when fluid leakage or thermal expansion takes place.