Die-Formed Toffee Candy Production Line

Request a Quote

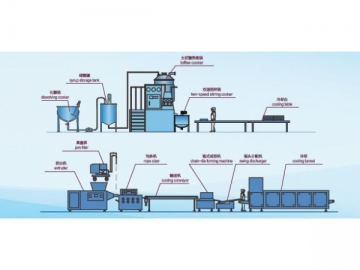

The die-formed toffee candy production line is comprised of the toffee cooking machine, caramel cooking machine, pulling machine, jam pump, candy extruder, chain type forming machine, shaking distribution conveyor, cooling conveyor and the refrigerated cooler, thus facilitating the manufacturing of different toffee candies, including soft filled toffee, filled toffee (eclairs) and caramels.

This production line features a high efficiency and high output. With a fully automatic production process, it requires only 4 people to carry out everything from raw material preparation to toffee candy formation, thus significantly saving on labor costs.

Manufacturing Process

- 1. Place rationed glucose, granulated sugar and other raw materials into the toffee cooking machine.

- 2. During the aerating process, add other materials, including monoglyceride, condensed milk and gelatin.

- 3. The sugar paste will then undergo cooling, ordering, and pulling.

- 4. The pulled sugar paste is extruded, while the jam pump is simultaneously opened with a proper jam flow set to centrally fill the sugar paste.

- 5. The sugar paste will then be pulled into a specific size using the rope sizer.

- 6. After cooling, it will be sent to the forming machine, then to the refrigerated cooler via the shaking distribution cooler.

- 7. The cooled candy is then packaged.

Standard

- Toffee cooking machine

The toffee cooking machine is designed to cook a variety of candies, including toffee, eclairs, and caramel. Candy is heated via a steam stirring process to effectively prevent charring. - Forming machine

The TLC-300 chain type forming machine is a vital piece of equipment in the production of toffee candy. The chain type structure significantly increases the amount of central filled material while preventing leaks, bursts, and adhesion to the mold. This machine effectively improves taste and quality of the produced candy. - Refrigerated cooler

The TLG-300 refrigerated cooler is equipped with the three- layer conveyor belt and refrigeration cabinet. This machine features a circulating cooling process, as well as a compact, small and easy to maintain structure.

Optional

- CRS series dissolving and mixing unit with automatic weighing system

This system will automatically weigh, mix, and dissolve glucose, granulated sugar, and other ingredients. The dissolved syrup will be stored in a tank for other equipment usage. This equipment is PLC controlled for an extreme precision, while the formula is preset and stored via PLC. It is a necessary piece of equipment for continuous production of toffee candies. - Jam pump

The jam pump is designed for central filling of eclairs, hard candy and jam toffees. The filling effect is precise and uniform. - Fondant rolling machine

The fondant rolling machine is equipped with two rollers made of a jacketed pipe and a whipping stick made of stainless steel. Fondant manufactured using this equipment is a fine, smooth and pure white fondant.